For the final project, my partner, Brian, and I decided to make the bishop chess piece. We initially thought this would be a good choice due to its symmetry, but ultimately decided to include the slit on the top of the piece (as in the Staunton chess set), which made it a little more complicated.

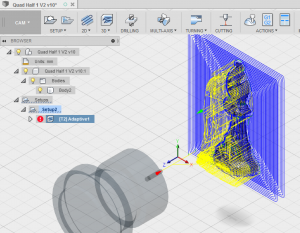

The first step was to prep a file for cutting on the Flashcut CNC. We downloaded the bishop pieces provided in the OpenSCAD Chess set by TimEdwards on Thingiverse. We initially thought that his set would be convenient since the pieces are provided both whole and as two halves. However, we found that using the half pieces created problems when trying to create a watertight solid for machining. Thus, we ended up importing the full bishop .STL file into Autodesk Remake, decimating the object and saving it as a .OBJ (quad) file. This was an important step in prepping the file for machining because the mesh created in Autodesk Fusion 360 is a quad mesh, not a triangle mesh (which is the typical form that .STL files take). After we got the file saved as a quad .OBJ, we imported to Fusion 360 and cut it in half. We then took each half, converted it from a quad mesh, to a t-spline body, and finally to a watertight solid, using the tutorial provided by Autodesk.

This object could then be used to generate gcode. We specified a bounding box the size of our wood block, with the half bishop at the center. We specified a tool path such that box was milled away, leaving only the positive of each half-bishop. This process was achieved by following a tutorial at Othermachine.

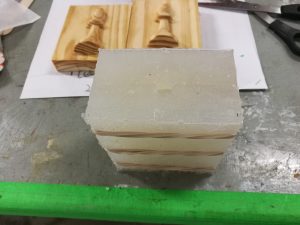

In an earlier test run, we learned that there was a line of code (M9) that needed to be deleted before running the program. This line specifies the machine to start the spindle, but on our machine this is done manually. We also learned that using Easel’s Fusion 360 post-processor made the gcode more compatible overall (reduces the number of errors — we only encountered the M9 error after using Easel). Finally, we were able to cut our positive pieces. We ran the CNC to cut each half of the bishop, which took about 1 hour per half. After this was done, we post-processed our wood blocks a bit by sanding them down until they were pretty smooth so that the final cast pieces would also be smooth.

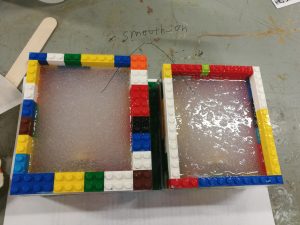

To create the mold, we took each positive wood block, created a box using legos, and poured in a Smooth-On product called SORTA-Clear, since the Oomoo was contaminated and no longer functional. We left this to cure for 24 hours. The next day, we found that the mold appeared very bubbly (the instructions specify that the SORTA-Clear should be degassed by a vacuum if possible, but we didn’t have the capability), and also a little sticky. It’s possible that we didn’t mix the 2 parts of SORTA-Clear well enough, but we did follow the 3 minute guideline for mixing. Nonetheless, the two halves of our mold were solid and functional for casting. We then took some time to create a hole in the bottom of the mold through which we could pour the liquid plastic material.

To create the mold, we took each positive wood block, created a box using legos, and poured in a Smooth-On product called SORTA-Clear, since the Oomoo was contaminated and no longer functional. We left this to cure for 24 hours. The next day, we found that the mold appeared very bubbly (the instructions specify that the SORTA-Clear should be degassed by a vacuum if possible, but we didn’t have the capability), and also a little sticky. It’s possible that we didn’t mix the 2 parts of SORTA-Clear well enough, but we did follow the 3 minute guideline for mixing. Nonetheless, the two halves of our mold were solid and functional for casting. We then took some time to create a hole in the bottom of the mold through which we could pour the liquid plastic material.

After doing this, we aligned our mold and placed rubber bands around it (very carefully, since we didn’t add keys to our positive pieces). We then mixed and poured in Smooth-On Smooth-Cast 300Q, which took only about 5 minutes to cure. After removing the piece, we found that some light post-processing was needed to correct slight misalignment in the mold and some roughness from the original wood positive pieces. We used a dremel to widen the slit on the top of the bishop and correct any major defects, then sanded until the piece was smooth. We did completed this process again, with the inclusion of black ink in the Smooth-Cast to create a black bishop. As a side note — we also couldn’t find the ink to start with and attempted to use black spray paint… but the results weren’t great. It affected the curing of the plastic and made it more maleable in the end. The black paint also rubbed off a bit.

This project was pretty enjoyable and taught me a lot. Prepping the files was the most challenging part, but I think that I could repeat the process now that I’ve done it once. Knowing how to use the CNC machine will be useful for future projects at the OEDK. And overall, I like the way our bishops turned out. In the future, I’d definitely take more time to create keys in the mold, which would save a headache later, but otherwise I think the process went smoothly.