For this assignment, I was put in the advanced group and we were instructed to laser cut a box with multiple compartments that would fit together without any glue. Okay. Harder than just cutting a normal box, but doable.

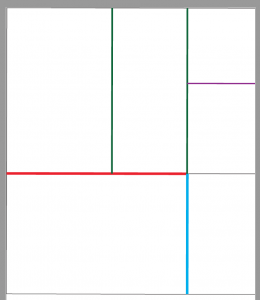

I started off by making the outline of the box on illustrator with the dimensions specified. This way, I could know what dimensions to put into makeabox.io to make the separate boxes. I quickly realized how much I missed the “measure” tool that SolidWorks bad because on Illustrator, the only way to know how long a line is is to trace over it with another line and then remember that measurement. So, I traced over the lines and took that time to mark what different separators I needed to cut.

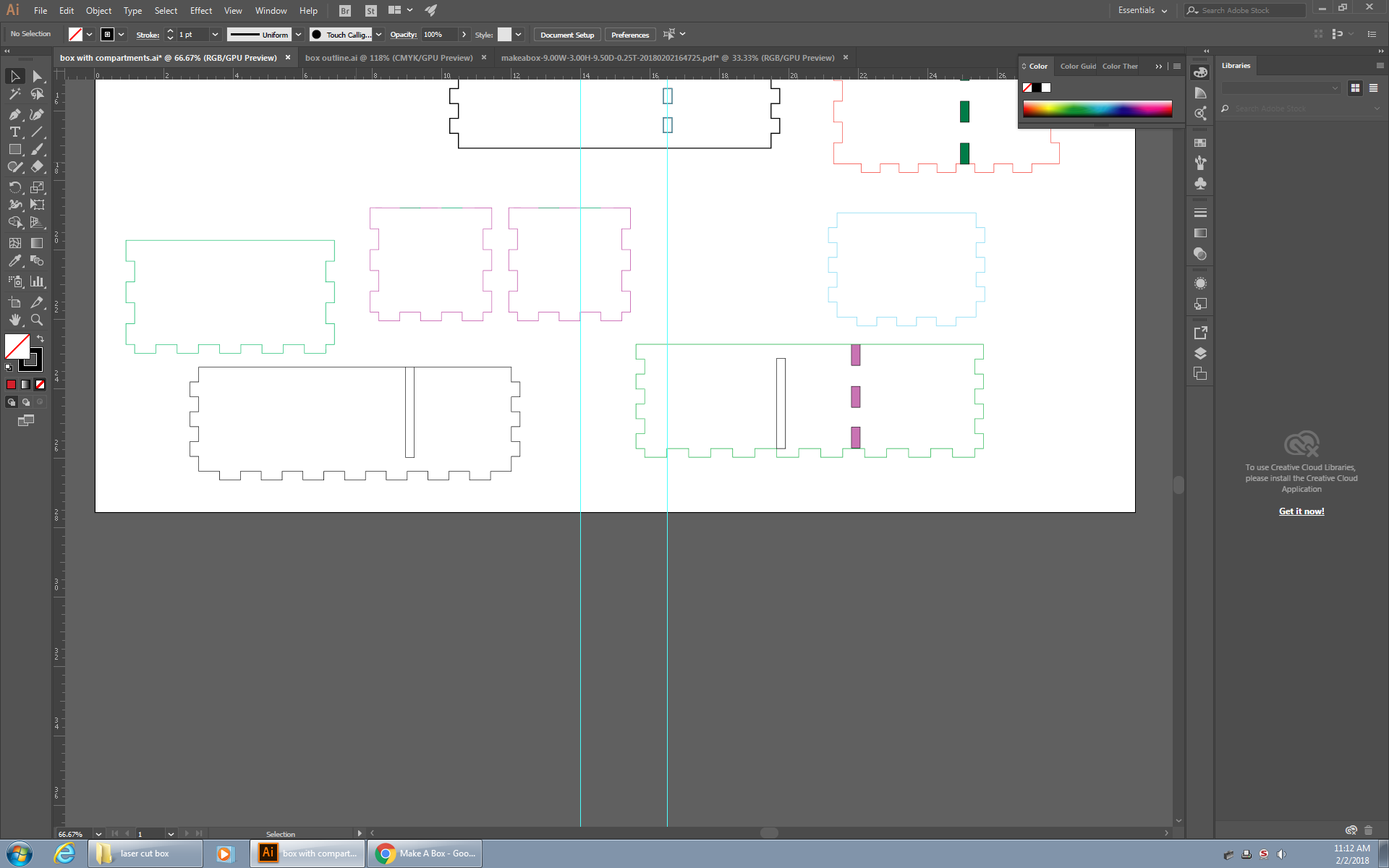

First, I cut the outer box that will encompass all the separators. Makeabox gives you a PDF file so I had to import it into illustrator and then use shapemaker to make all the different lines into a shape. After that, I started cutting the inside separators. My biggest issue was the 4 way intersection because I would somehow have to fit four different pieces into the same point. I thought about it for a while and then I realized that I could just modify the separator so two long separators would fit over each other.

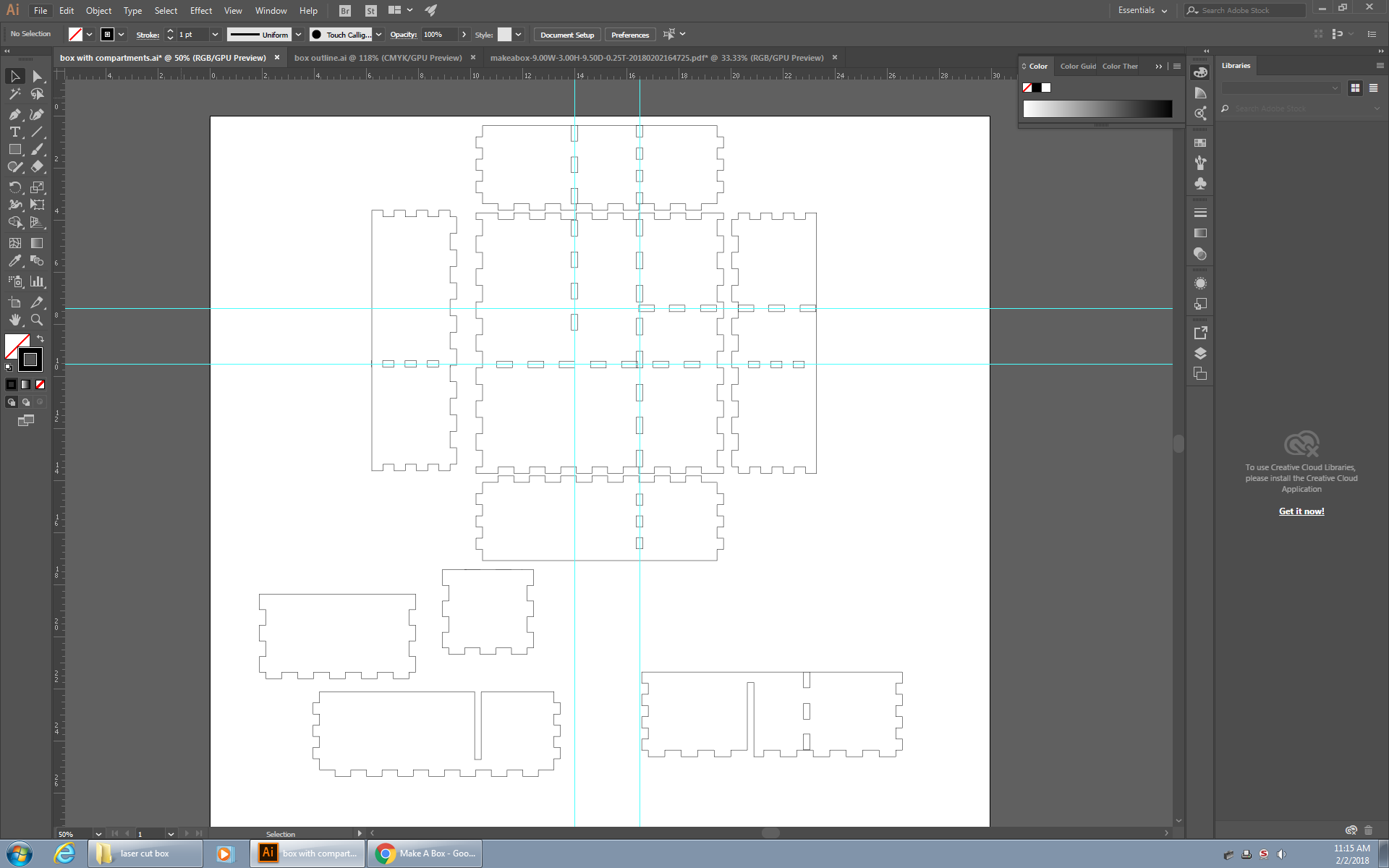

After making all the separators, I had to make the joint holes in the big box. I did this with a lot of guides to make sure that they were in the correct location. I put guides where the separators are supposed to go using the outline to help me. To make the holes the right size, I traced over one of the joints and the just copied and pasted it into the right location. However, I realized that some of the joints were different sizes so I figured out a new approach where I duplicated each of the separators and then drew a line to divide the joints and then used shapemaker to separate the joints. Then, I took the joints and placed them in the big box. Wow, what a process.

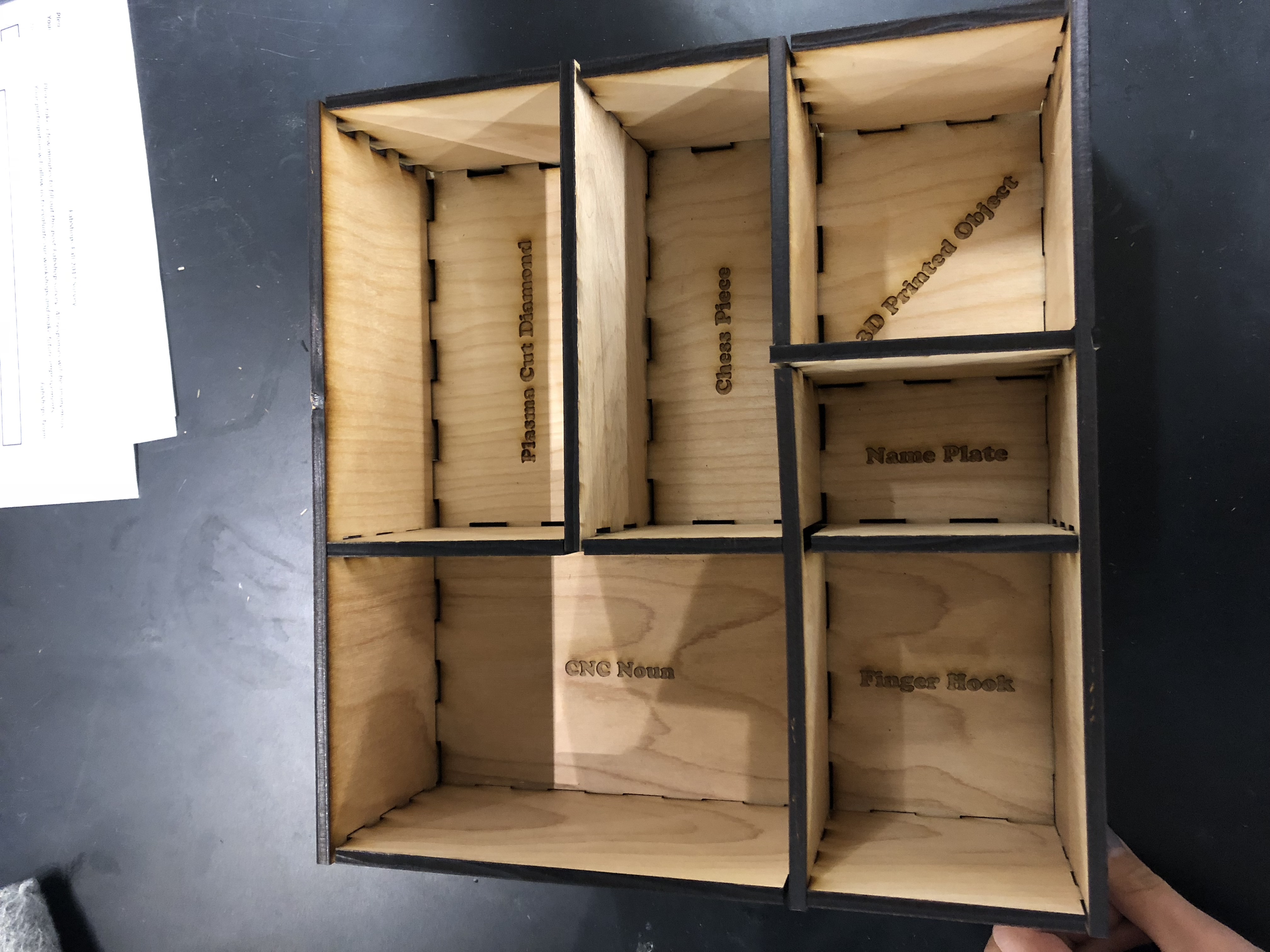

After all of that, it was finally time to laser cut. My first iteration was mainly to tell me what I was missing. It turns out, I forgot some of the holes, some of the holes were mismatching and the 3 by 3 separator was too big. Not too bad for a first try. So I went back and fixed the mistakes and then reprinted it. I also added names to the compartments so I know what goes where.

The 3 by 3 separator was still too big and I noticed that the joint holes were a little off, so I repeated my process and recut the separator.

I jammed in the 3 by 3 but you can kinda tell the long separator is misshapen because the separator was too big

Now, the separator (kind of) fits in there. Now, I had to assemble the rest of the box, which was a little bit of a struggle. It was like putting a puzzle together because all the pieces looked the same. But, with a little bit of work, everything fit okay.

After making sure that everything fit, I sanded the box going from a rough grit to a really fine grit (I forgot which ones) so that the box would be really smooth.

After this assignment, I can confidently say that I know how to use illustrator, although I definitely prefer SolidWork’s engineering features. Also, if I were to do it again, I would measure the wood before making all the sections because the wood was not exactly 1/4″ so the joint holes were a little big.