One of our two latest projects was to use the Carvey desktop CNC machine to carve out a noun. For my noun I chose to do an elephant. The first step of this process was to find an appropriate image file on The Noun Project website. After doing a search for elephant, I quickly found an image that I liked and thought would look nice.

After a quick run through Illustrator to get rid of the attribution, I had my file ready to go! I looked through the boxes of provided wood for two suitable blocks but couldn’t find anything that really struck my fancy. So I decided to take two decent blocks and apply some stain to really get them looking the way that I wanted. I used red oak blocks and applied “Pickled Oak” stain to it. I chose this one because the others looked too dark and I had seen from other examples that thin lines on a dark piece can be a little difficult to see. I applied the stain and waited for a few hours before flipping them and doing the back.

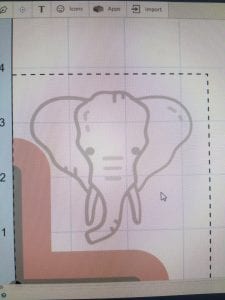

Once the stain was applied and dried on all sides, I put my file into Easel and adjusted the “wrinkle lines” on the elephant’s face to be slightly less deep to get a better contrast (1/16ths deep for the wrinkles vs 3/16th for the rest). Unfortunately, as I found in the end, the difference at an inital glance between 1/16ths and 3/16ths is barely noticeable.

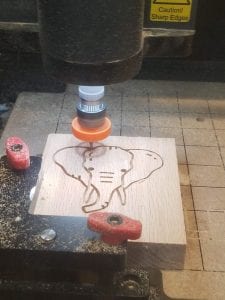

Once the file was done, I was ready to start carving! I set up the bit (1/32nd according to Easel) as well as trusty Francis the fan and clamped down the first block into the corner according to Easel’s directions. I pressed go and waited for the magic to happen. Unfortunately, about 3 minutes into carving, the bit broke! Sorry OEDK…

I wasn’t sure what the problem was so I asked a lab tech and he said that sometimes that happens and to try it again carefully so I flipped the block over and did just that. This time, everything went smoothly and it carved away.

Once that was done, I clamped down my second piece of wood and pressed go and let it carve. Fortunately, everything continued to go smoothly and I had my two CNC carved pieces! I cleaned up the Carvey and the next step was to do some quick post processing. There wasn’t really all that much to do other than get rid of some small wood shavings in the gaps and smooth out the edges. I vacuumed up the shavings out of the gaps and go some sandpaper for the edges. My lines were thin enough that just by folding a piece of sandpaper in half, I could squeeze it into the lines and sand the edges that way.

Once I was done with that, I had two beautiful carved elephants and was pretty much finished with this project!

Cost Analysis:

Raw Materials:

3.5″ x 8″ x .75″ Red Oak: $3.76

Pickled oak wood finish: $17.91

Total raw materials cost: $21.67

Labor:

Time spent: 4 hours

Minimum wage in Texas: $7.25

4 * 7.25 = $29.00

Total labor cost: $29.00

Machine Cost:

Monthly membership to makerspace with CNC machines: $50

Total machine cost: $50

Total Cost: $100.67