For this project I chose to print this 3d printable fabric

I chose this object because the small single piece units interlock in a way that would be impossible to manufacture any other way. I also chose to use the maker gear printer and the fortus printer. To print this part on the maker gear I downloaded it and opened it with Ultimaker Cura.

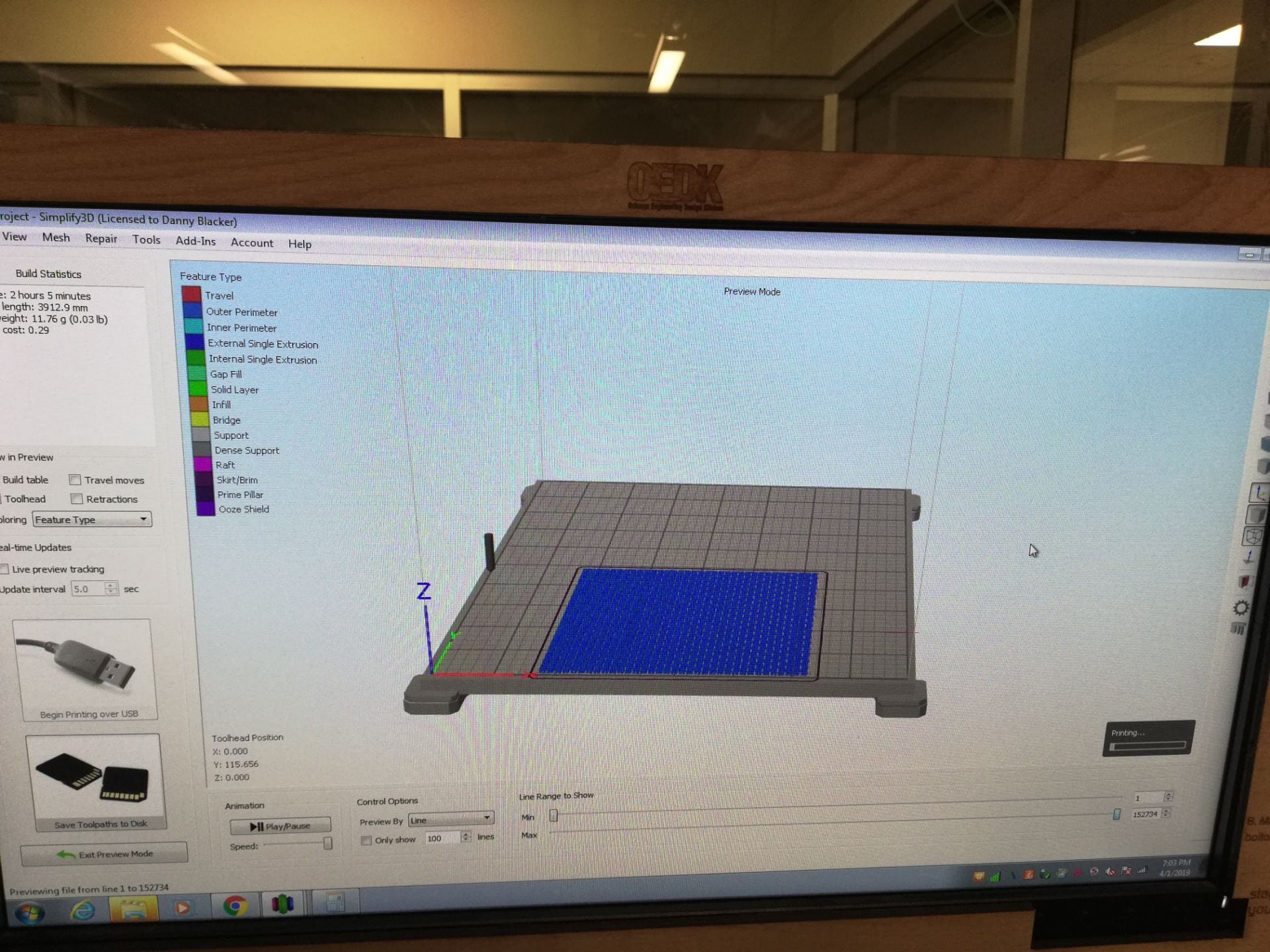

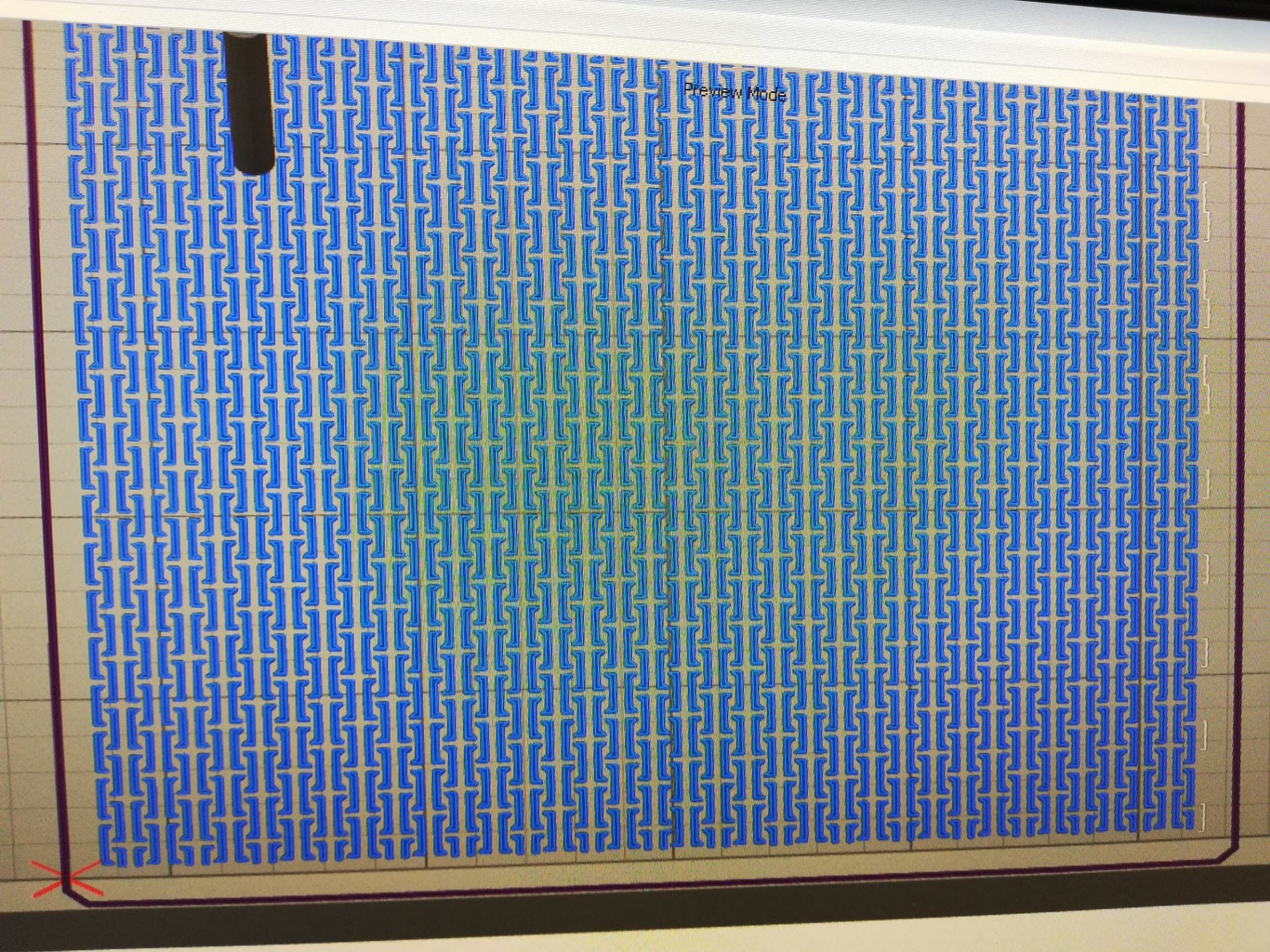

The intricacy of my part meant that I couldn’t use typical build plate adhesion features such as rafts or brims because removing them later would likely result in damage. Because of this I chose the default settings for .2mm layer height and generated the print file. I then checked the print file to ensure that all the small features would be printed properly.

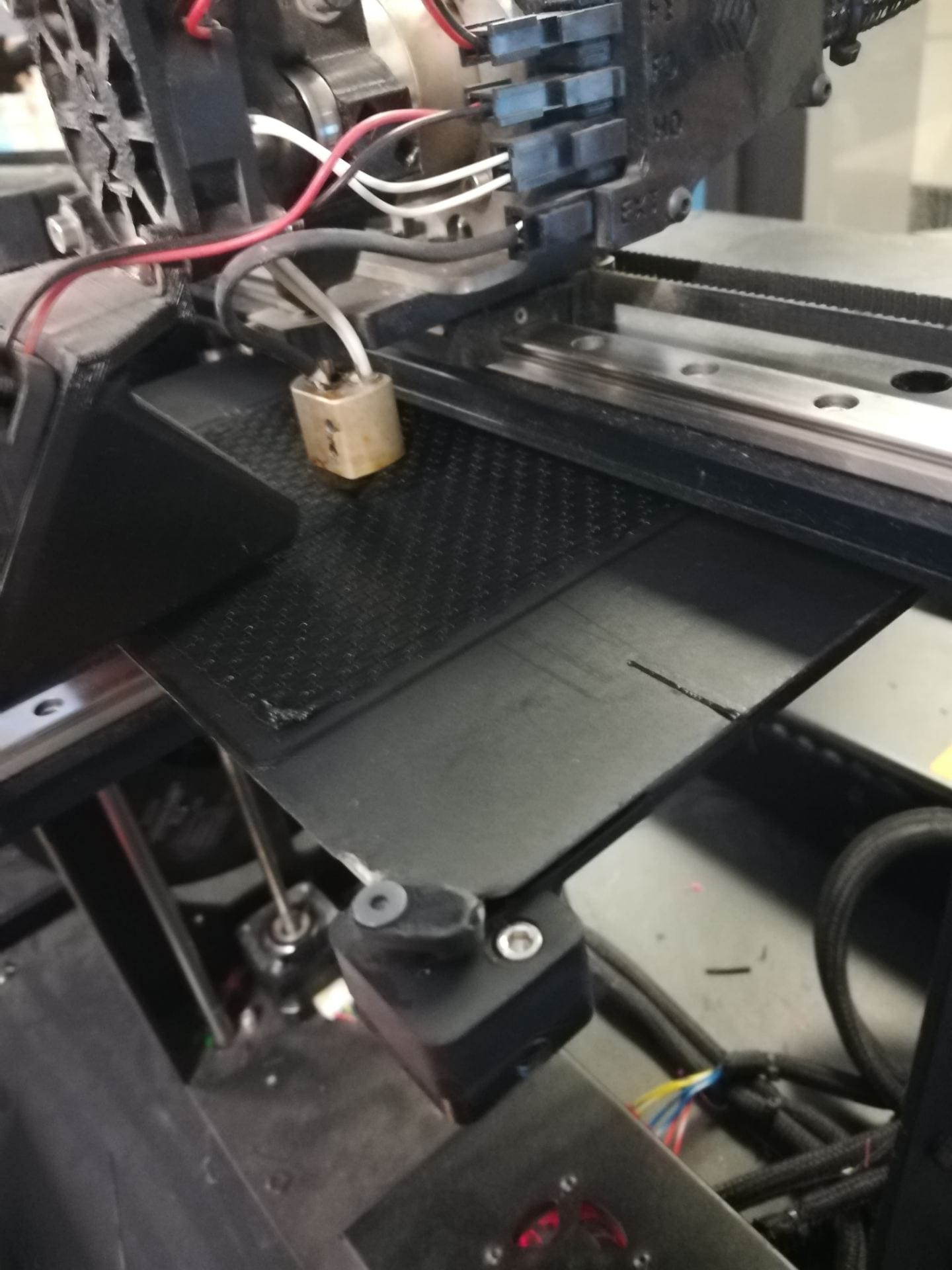

I then sent the file to the printer and watched to make sure it was printing properly as the majority of errors resulting in a print failure occur during the first layer. The particular machine had a slightly warped bed which resulted in a failed first attempt. Luckily it was a removable magnetic flexible build plate which allowed me to slip small pieces of paper between the build plate and carrier which allowed me to correct for the warping.

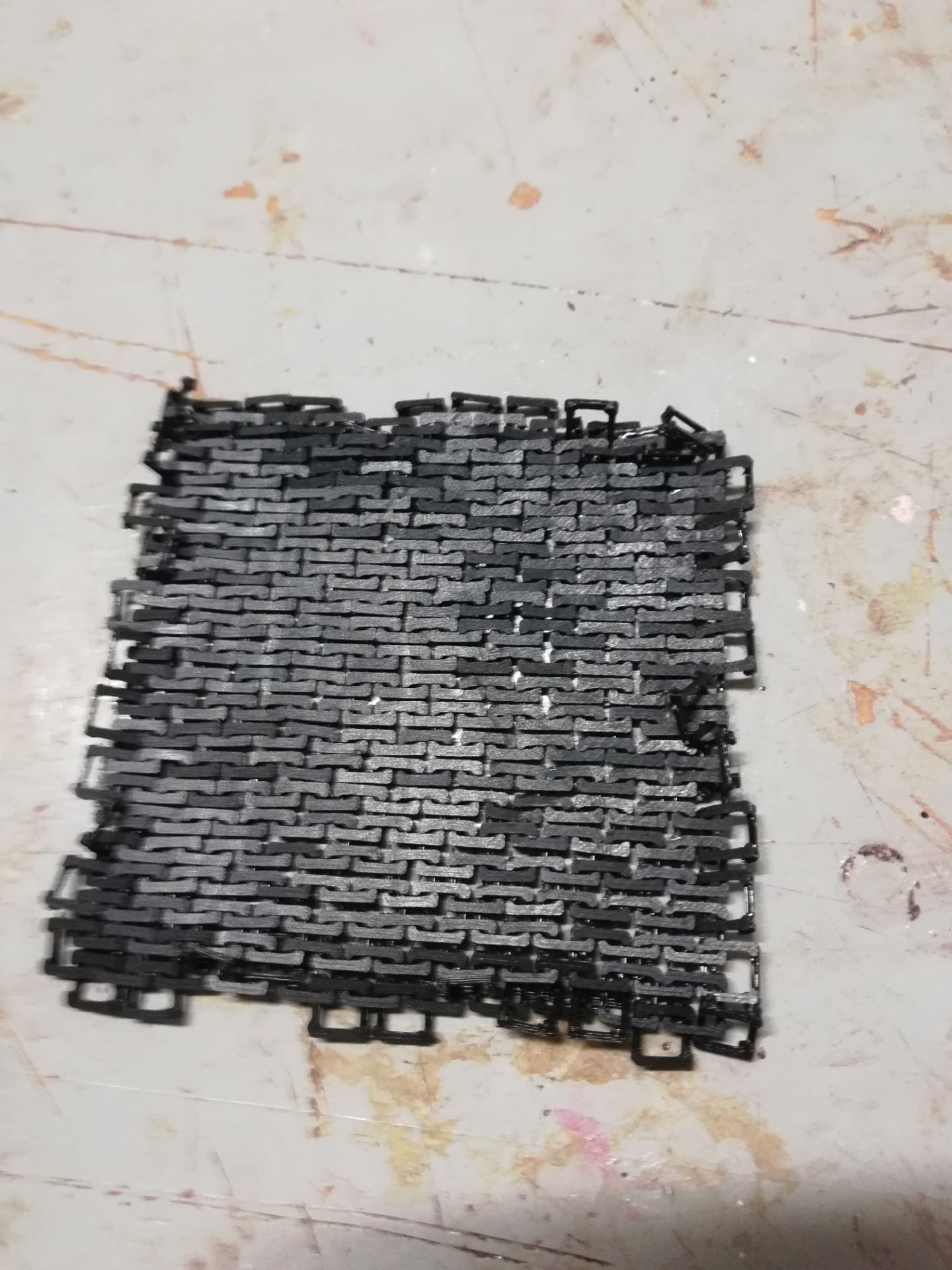

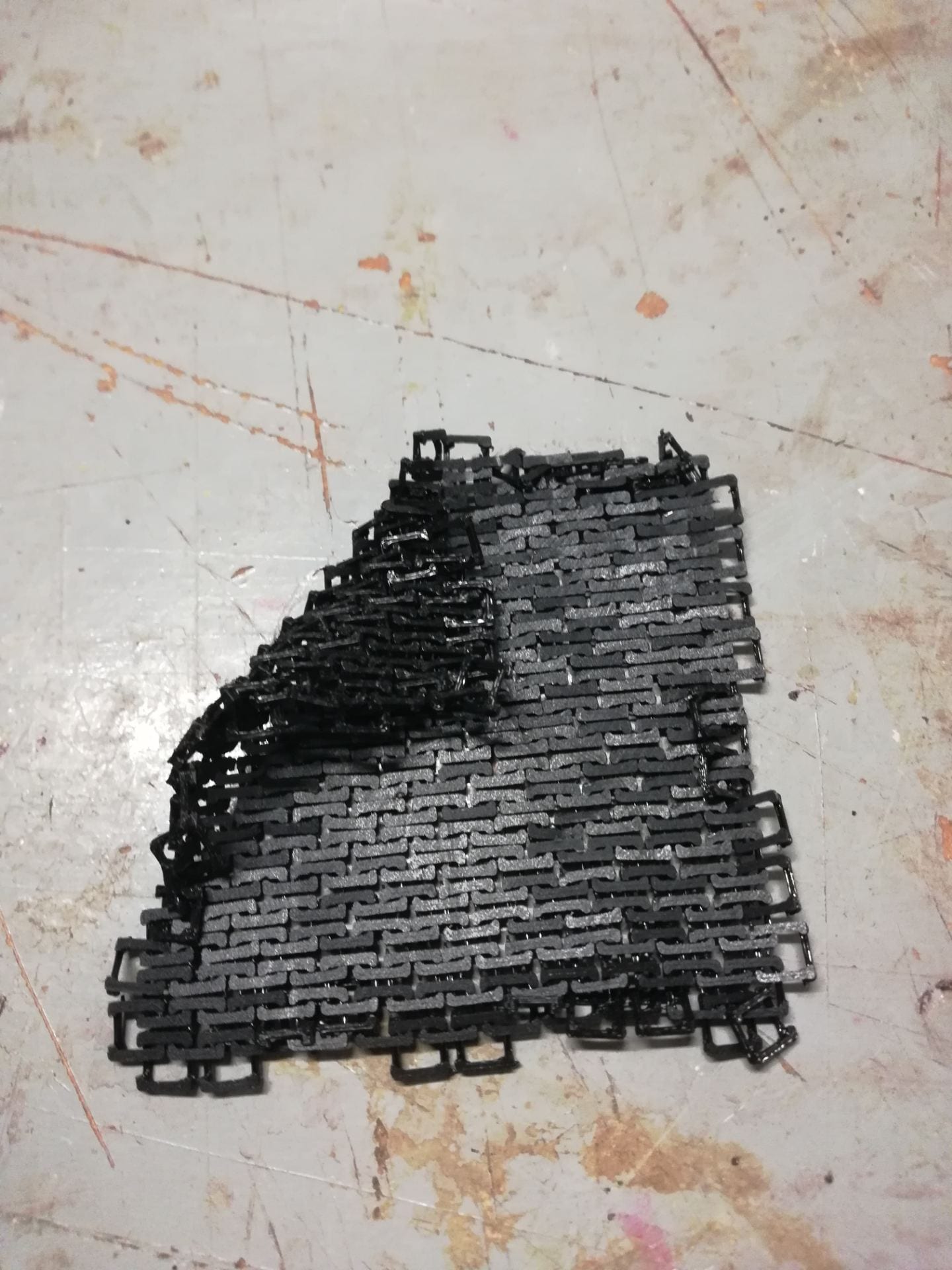

As can be seen, there were some small failures around the edges. Luckily since it was my intent to print this piece too large and then cut it down to fit in the capsules, this was not a problem. After my print was complete I removed it from the build plate with a spatula (normally this would be done by flexing the build plate to pop the part of, but in this case my piece was also flexible and moved with the plate). once it was off I cut it to size and kneaded it for several minutes to break all the small wispy bits of plastic which connected each of the small interlocking pieces. I was left with a flexible, surprisingly fabric-like piece.

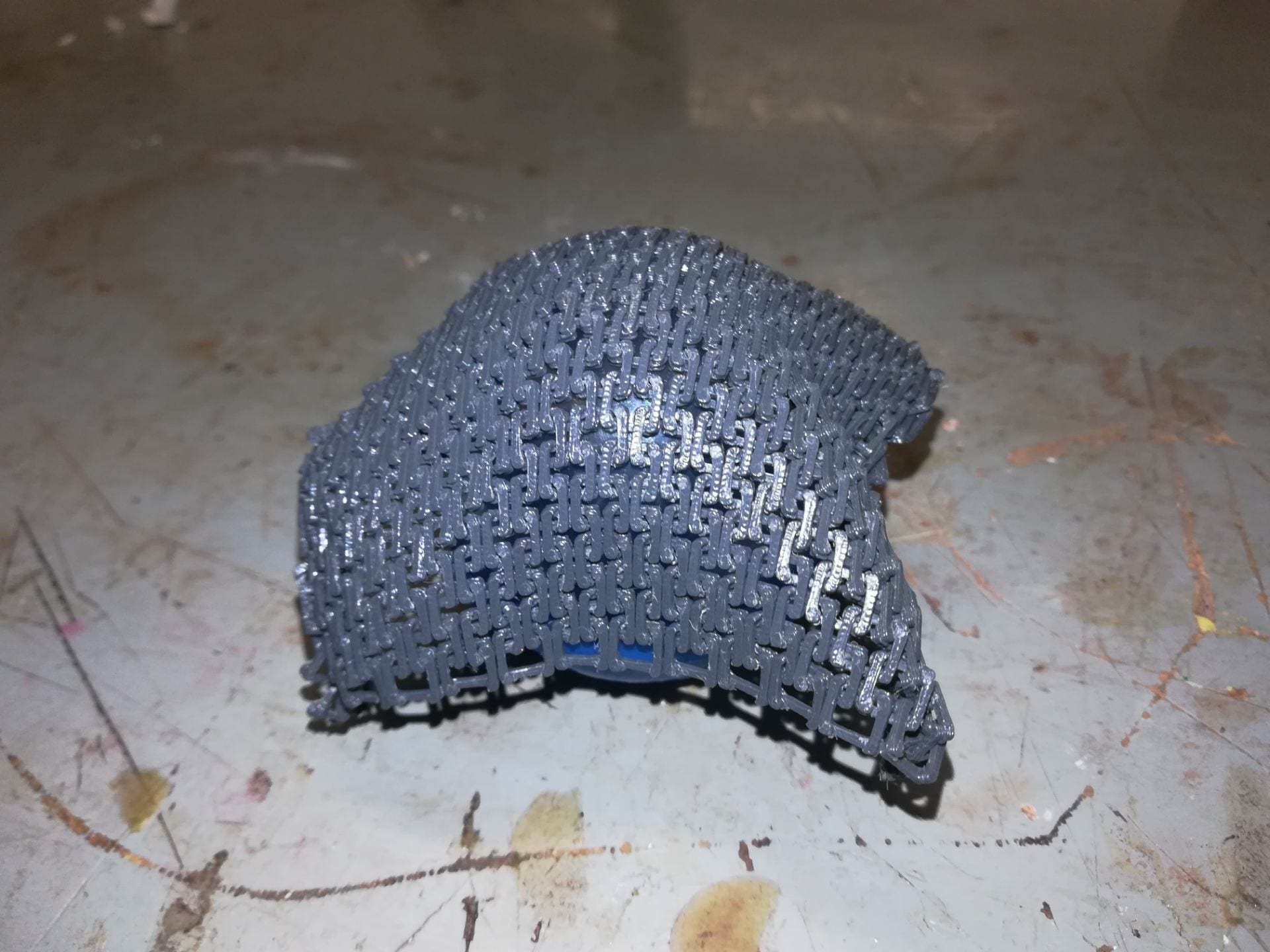

The process to print this on the fortus was very similar to the maker gear. I loaded the file into the fortus software, used default settings, sent the file to the printer, placed the build plate (disposable on the fortus) and hit print. for this machine I did not have to make multiple attempts at getting the first layer to stick because the fortus uses a dual material system in which one material is soluble. This meant that I could use a raft and then gently remove it with a lye bath after the print was done. This print was much more fluid than the maker gear version.

Altogether I spent about an hour to prepare and post process the pieces which at a rate of $20/hr costs $20. the OEDK quoted the fortus use to be $17.96. Given that a roll of PLA plastic costs around $20 and I only used part of one for the maker gear print, I will estimate the cost to be 1$. This brinks the total cost to about $39 for both parts.