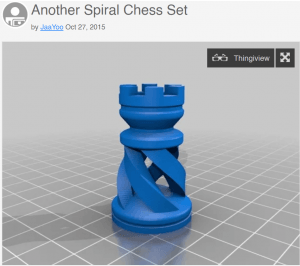

For my 3D printing project, I manufactured a spiral rook (figure 1).

My process was as follows:

1. Obtain STL

Using a 3D printer requires a toolpath file — luckily, almost every 3D printing human machine interface can take in a standard tessellation language (STL) and develop G-Code from it. Therefore, all I needed was an STL of my object. For this, I went to thingiverse.com and downloaded the STL of my object (figure 2).

2. Print

On the makerbot, this simply meant adjusting a few system settings such as:

- Layer Height: 0.3 mm

- Support: On (15% infill)

- Infill: 25%

The makerbot print took roughly 40 minutes while the Fortus took about 1 hour.

3. POST PROCESSING

This step required using pliers to remove any support material or inconsistencies in the print.

Cost estimation:

1. MATERIALS

The materials used in this model were: Polylactic Acid (PLA) and Acrylonitrile, Butadiene and Styrene (ABS). These are both quite expensive, and we can estimate the total cost to be around $40.

2. LABOR

While the print times were lengthy, the setup and post-processing were the only real man-hours (roughly 30 minutes). At $15/hour, this comes out to $7.50.

TOTAL COST: $47.50