The Inspiration

Building just any old crate is boring. So why not make a crate that you can play a game on? I can just do that by lowering the pillars on the beginner crate and adding a lid right? was my thought going into this process. Little did I know the amount of effort this project would take (totally worth tho).

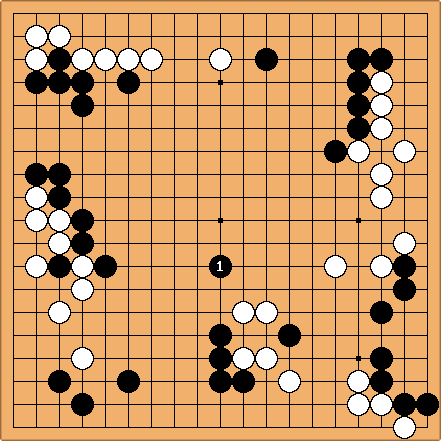

So recently I got into the board game go (aka baduk or weiqi), which is an ancient game played using black and white stones about securing territory. It’s played on a 19×19 grid of a set size which is why the lid and create itself had to be so big. This is how I made it, plus all of the mistakes that I made along the way:

A sample go board position

A sample go board position

Lumber

- 6pcs 1×4 20 in

- 6pcs 1×4 18.5 in

- 2pc plywood 18.5″x18.5″ x 1/2 in thick

- 4pcs 2×2 9 in

- 2pcs 2×2 7 in

1x4s were used for the walls, plywood used for the base, and 2×2 used for the support pillars and handles.

I cut the 1x4s and 2x2s using the miter saw and the plywood using the tablesaw. I accidentally measured wrong and cut like 4 pieces of lumber too short so I had to find more wood. I then proceeded to make the same mistake again but decided to roll with it (originally the 1×4 was going to be 21.5″ in not 20″).

I used the table router to round the edges of the 1x4s. Some edges seemed to be routed already which saved me some work.

One thing I wish I did was claim some nice wood earlier, because I had some trouble finding wood which wasn’t cracked, discolored or chipped. I also wish I set the distance on the miter saw itself instead of marking the distance by hand because the the pieces ended up being slightly different lengths.

A lot of time initially was spent trying to figure out where to find everything I needed in the OEDK. Eventually I got it though. Pro tip: Lab assistants are your friend. Be a shameless noob.

Assembly (pt.1)

Then I used the corner clamp + drill to assemble the first 2 layers of walls. I was careful to line up the screws as best as I could because they were relatively thick and I didn’t want them to crack the wood.

The walls didn’t align perfectly into a rectangle, so I used the belt sander to align the edges after assembly.

Then I sanded everything down using an orbital sander, including the base. During this time I also tested out laser engraving the go board on the base piece of plywood, which you can see in the corners.

I also tested sawdust + wood glue as a makeshift wood filler to try to fill in some of the holes in the wood. It was meh, I think the sawdust needs to be somewhat fine-grained for this to work effectively.

Assembly (pt.2)

Sanding everything made the rest of assembly much smoother since it reduced the risk of splinters. I saw another student use the pro trick of having 3 separate drills for drilling the pilot hole, countersink, and for screwing, which I copied and saved so much time with since I didn’t have to switch the bits after every 2 screws.

I attached the bottom base to the walls, and then the pillars to the walls. I assembled the final layer as well.

Originally the idea was to have gaps between the wall layers, but after assembly I realized the pillars would be too short, and so I just stacked them on top of each other. I contemplated having a gap between the 2nd layer and the top layer so that there would be space to fit some fingers through to grab the crate, but I decided to just go with simple handles on the side instead, which I screwed from the inside.

Post-processing & Finishing

I decided to use Danish oil to finish my crate. I wanted to keep the natural look and grain of the wood; I figured it would add some character. I did a couple of coats on the crate and handles and it seemed to work pretty well.

The Lid (nightmare)

Now it was time for the lid. I used the table saw again to cut a slighter smaller than 18.5″x18.5″ piece of plywood, then used a flat 45 angle router bit on the edges to fulfill the proficient requirement.

Ok so this is where I probably made the biggest mistake of the entire project. I wanted to laser engrave the go grid onto some plywood which I could use as the lid.

After testing it though, the lines didn’t appear as dark as I wanted them to be, so a lab assistant suggested spray painting it black, then sanding off the top layer. This was a terrible idea (no offense to the lab assistant, he was super helpful). It turns out that sanding spray paint is really difficult because it 1. seeps into the grain of the wood so you have to sand DEEP and 2. it gums up sandpaper so after a few seconds of using the orbital sander it renders it useless.

So after laser engraving the lid (this took 45 mins btw), spray painting it black, and attempting to sand it (with the orbital sander and also by hand), I just decided screw it, plan B. I took a thin sheet of MDF from the wood shop and laser engraved it again (another 45 mins), and this time also vector cut it out. This time I used black marker to fill in the lines to make it darker.

I then used wood glue and some clamps to attach it onto the lid piece. I know the assignment technically doesn’t allow wood glue but because the MDF sheet was so thin it didn’t really make sense to use screws. Also because the lid is a nonessential part of the crate I figured it would be ok.

Then, it was complete. I decided to not use any oil finish on the MDF sheet since I didn’t want to make it darker and MDF is pretty dense and technically already finished anyways.

And that’s it. Overall it was a lot of fun to build this crate. I purposefully challenged myself and tried to use a variety of resources at the OEDK and learned a lot about woodworking. In the future maybe when we make the chess pieces I can laser engrave a chess board on the other side of the lid.

goofy selfie with my chonky boi (im so tired)

Cost

2×2 Wood: 50″ – $12 (Home Depot)

1×4 Wood: ~20 ft – $10 (Home Depot)

Plywood: ~6 sq ft – $14 (Home Depot)

MDF 1/8″: ~3 sq ft – $8 (Home Depot)

Screws/Sandpaper/Other small items – $3

Danish Oil Stain: approx. $3 worth

Labor: 15$/hr for 15 hrs — $225

Tools: Assuming $50 for a makerspace membership

Total cost of materials: $40

Total cost: $315

I think if I did this again I could probably do it 2-4x faster.

@dk.academia im back kinda xddd… shoutout to the cool ta who helped me be less of a clown lmao

@dk.academia day 2 les goo btw im a woodworking noob so dont take anything i say too seriously LMAO

@dk.academia assembly time… almost there #woodworking

@dk.academia aaaand finally its finished…. did not expect it to take this long but totally worth it B) #woodworking #gogame #baduk #diy