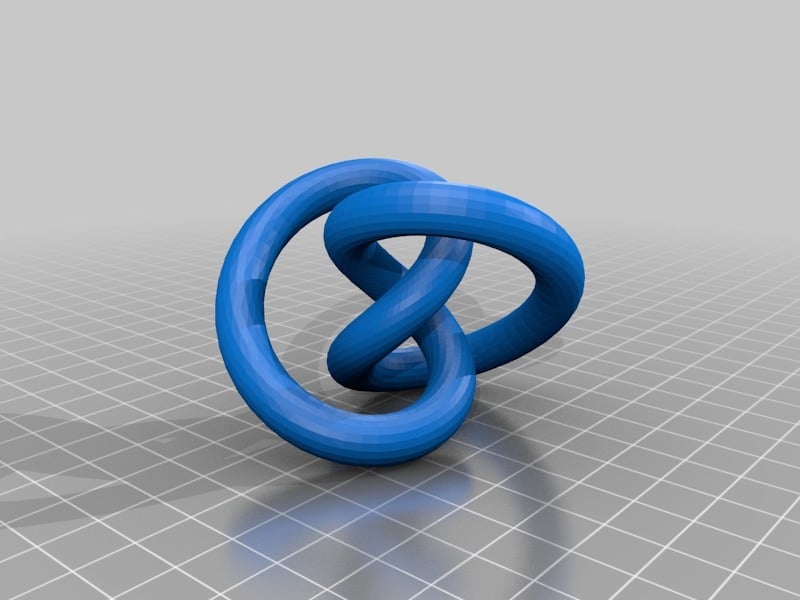

When I was originally assigned this project I had no idea what I wanted to make and how to make it impossible. I started looking at old Engi 210 assignments, sculptures, and artworks. After looking for some inspiration I decided on a knot, but a knot that existed as one piece, so it would be impossible to carve or create through other means. I discovered the “Rolling Knot” by Kitwallace on Thingiverse and instantly decided I wanted to make this. https://www.thingiverse.com/thing:230557

Figure 1: Rolling Knot 2D render

For this project, I used FDM and SLA printing. I printed 4 copies using FDM and the last copy using SLA printing. For FDM printing I used the Bambu X1 Carbon 3D printer with PLA filament. For SLA printing I used the Formlabs Form 3 printer.

For FDM printing I encountered no problems and it was very smooth. The process I followed can be found below.

- I opened Bambu Studio Slicer

- Imported my STL file

- Scaled the file down to fit in the capsule

- Set the layer height to 0.15 mm

- Sliced the file and added supports

- Finally I sent it to the Bambu X1 Carbon 3D printer #9.

The prints came out as I expected and the supports were easy to pop off with my fingers.

Figure 2: FDM Print of Rolling Knot

For SLA printing I encountered no problems and it was very smooth. The process I followed can be found below.

- I opened the PreForm Slicer

- Imported my STL file

- Scaled the file down to fit in the capsule

- Automatically oriented and generated supports

- Sent it to the Formlabs Form 3 Printer

- Wash the print for 15 minutes

- Cure the print for 1 hour at 70 degrees Celsius first letting the machine Pre-heat for 12 minutes.

- Remove supports once done.

The print took 3 hours and 30 minutes and came out great with no issues or defects.

Cost:

- Materials: Free provided by OEDK

- Labor: $30 (2 hours @ $15/hour)

Total: $30