In class, we started the process of creating and pouring the molds. First we made the mold by mixing alginate and water together. I did a 1:1 ratio of alginate to water by volume. I then put my fingers in the mold and waited for it to set for a couple of minutes. Once set, I mixed together the casting material with water in a 1:1 ratio and poured it in the mold. I added screws and suspended them with tape and a popsicle stick.

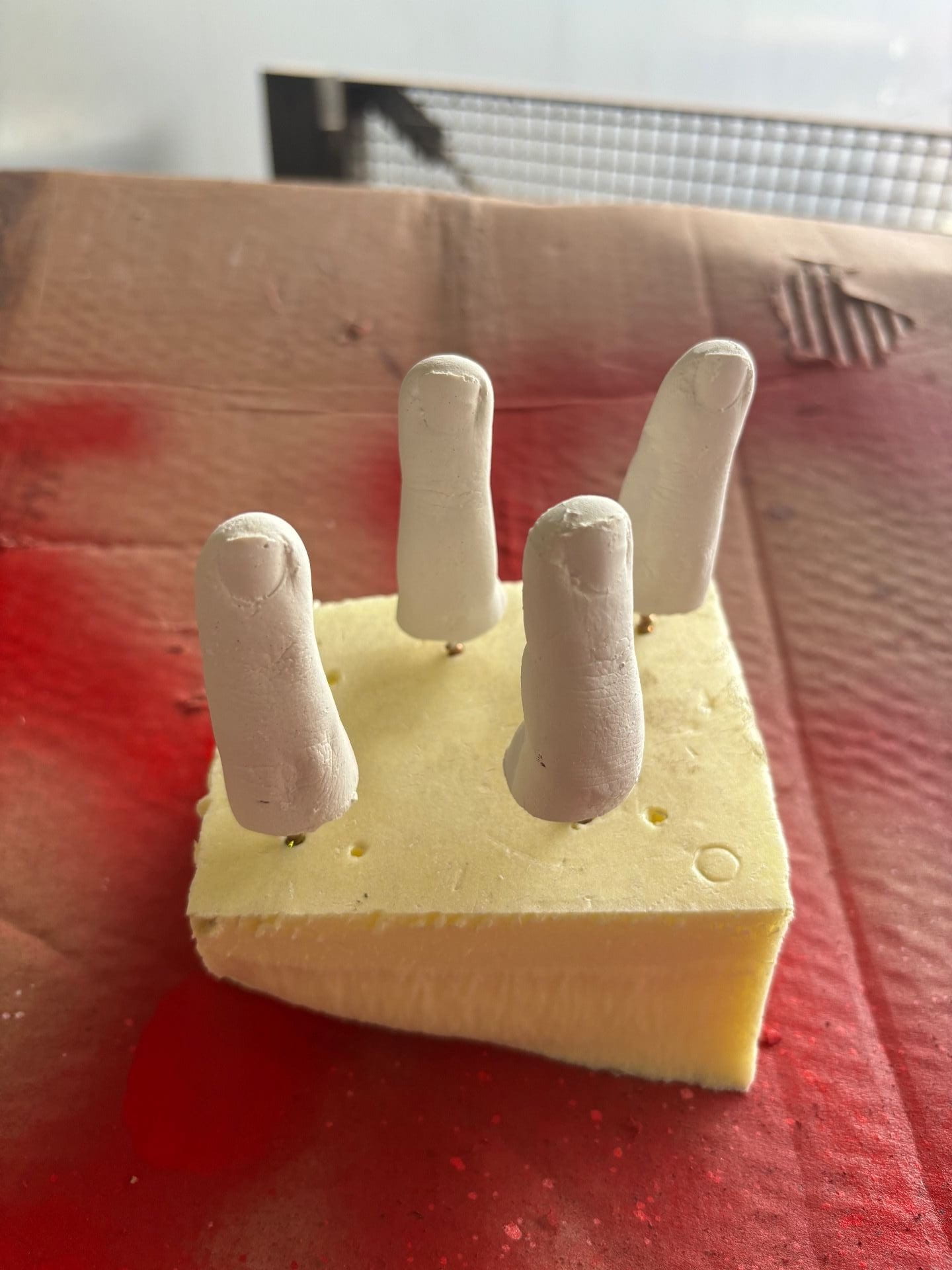

Figure 1: Result of the first round of casting

After allowing the casting material to set, I removed the fingers and repeated the casting material process to make another set of fingers so that I would have an identical set.

Figure 2: Two sets of almost identical fingers

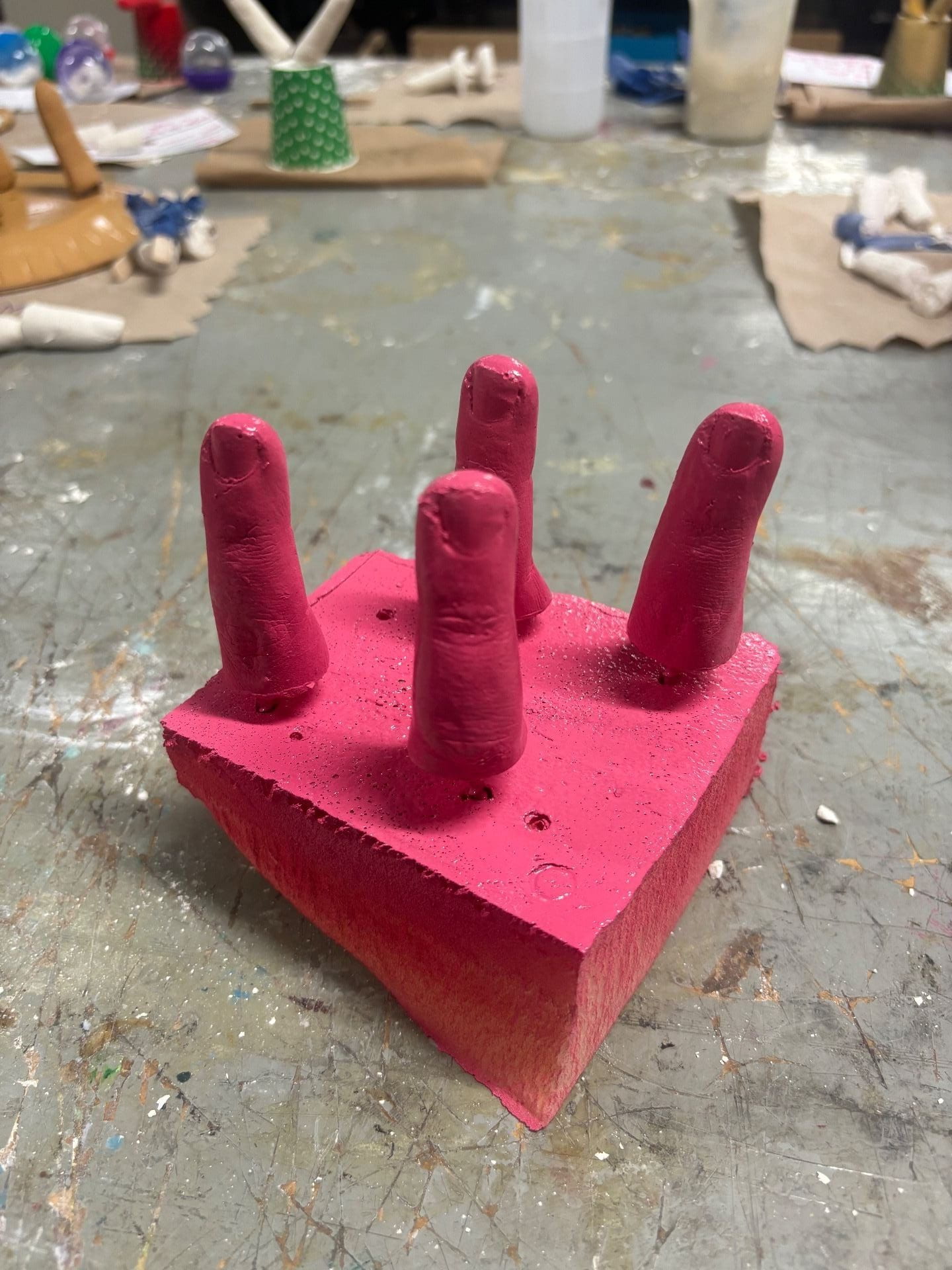

I used foam to support the fingers and then spray painted them.

Figure 3: Fingers in foam before spray painting

I did two coats of pink spray paint and then one coat of clear enamel.

Figure 4: Final fingers

Cost of Production:

Alginate $10.99 for 0.68kg. 150ml is about 68g so cost is $1.10.

Plaster of Paris $14.98 for 3.62kg. 100ml is about 225g so cost is $0.93.

Spray Paint $5.98 for 12oz. Used approximately 1oz so cost is $0.50.

Clear Coat $11.99 for 11oz. Used approximately 0.5oz so cost if $0.55.

Labor at $15/hr for 1.5hrs is $22.50.

Overheads at 15% of total cost is $3.84. This covers OEDK costs such as lab assistants and extra materials like tape.

Total Cost: $29.42

Clean Workspace: