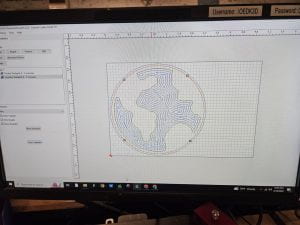

In the past few weeks, I learned the basics of how to modify and create a CNC tool path and use the CNC machine to cut the design out. On the Noun Project website, I searched for a design of the Earth. After I found my desired design, I downloaded the SVG file and imported it into the Carbide Create software for the next step.

I measured the dimensions of the plank wood that I was going to use for the cut. Then, I created the tool path of the desired shape, size, and depth with the help of the software.

Then, I need to set up the Nomad 3 CNC machine. I taped the wood piece onto the bed of the CNC machine and then placed the zero-probe device on the left-down corner of the wood. By setting this up, I was able to zero all the axes of the CNC machine.

After all the preparations were set, I started to run the tool path I created.

The first piece was finished after around 15 minutes. The result looks great! The only thing is the surface is pretty rough and a lot of sanding is expected.

Then I started my second cut. During the second cut, however, something unexpected happened. The tape of the wood piece came loose and the wood piece started to move during the cut. I immediately stopped the machine. Unfortunately, this is a failed cut and I have to cut a new piece.

After I obtained all the pieces, I started the sanding process. I carefully sand the top, bottom, and inside patterns of the CNC cut. After sanding, I use the mineral oil to coat the surface to give the CNC Earth a fresh and clean finish.

Cost estimation:

Wood: $1

Labor: 2hr x $15/hr = $30

Machine fees: I’ll give an estimation of $50 for using the CNC machine for 1.5 hours

Total: $1 + $30 + $50 = $81