Ever find yourself doodling levers and bars in class? Thinking about peacocks rather than whatever’s on the board? Welcome to ENGI.

It is midterm season, and after hours of staring at mechanical movement 350, I decided to build my own mini fan opener. Hope you’re a fan.

(Jk, I just wanted a peacock. No practical reason/purpose.)

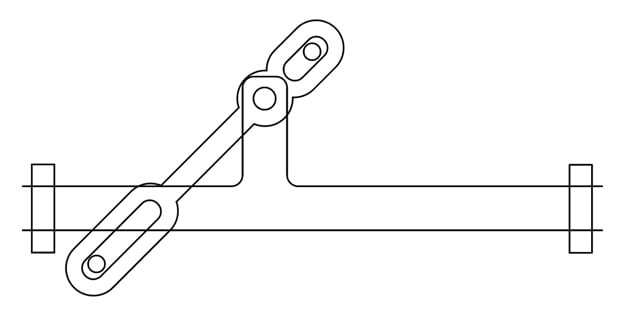

Starting with Illustrator, I flipped my 350 upside down and redrew it with truer shapes and desired dimensions. I even lengthened the horizontal slot and the lever slots, hoping to get a wider sweeping motion.

The first prototype consisted of laser cut cardboard, paper straw dowels, and a folded paper fan. The whole thing is held together by bits of hot glue.

To prevent the central lever from bending, I laser cut the piece out of wood instead–

These low fidelity prototypes gave me proof of concept and got me thinking more about spacing (dimensions… urgh) and the smaller elements I need– dowel stoppers (“donuts”), hinges, etc. But so far, I’m happy with what I’ve got.

My only concern was that the pins didn’t seem to reach the ends of the horizontal slot; they were somehow stuck an inch from the edge. I’ve tried lengthening the lever but to no avail. By Dr. W’s recommendation, I moved on to a medium fidelity prototype using wood.

The issue persists, but I focused more on refining the other elements of my project, drawing and cutting the donuts, the hinge-ish supports, and the umm… other part. You’ll see.

I spent a looot of time on this prototype, tweaking things and adding things (make key shorter, adjust kerf, raise stand with legs, etc.), and generally figuring out what parts I still need (how will the fan be attached?). And, while experimenting with both front and back sides, an idea hit me: if I put everything on the back, people could see the entire mechanism in action!

And so it is time to set upon on my final version. I plasma cut the lever, spent an hour processing it, burned my finger in the process (do NOT touch metal fresh from the angle grinding dremel), and decided to start over. Hello again plasma cutter. Good news, the new lever looks much better than the first cut. Not-so-good, I’m back to wire brushing (absolutely amazing) and the ol’ file and sand for another hour or so.

I got in the usual line for the laser cutter on the night before The Due Date. Several times. Changes were being made every second: adjust kerf to snap fit, new floorboard, more stable legs, bigger donuts to restrict movement direction, key with and without the other part, new peacocks to replace the ones I broke… the list goes on. In the meanwhile, I sanded the parts with sliding dowels, welcomed gorilla glue as my new best friend (sometimes nemesis… too many times have I moved parts that haven’t dried yet… does not end pretty), and found some cool paper from the Makerspace to be my peacock tail feathers.

Yet also, the getting-stuck problem is still there. Eventually I decided to put a handle on the horizontal slot. Moving that gets the whole thing going much more smoothly.

The time was no longer today. The peacock by itself would be presentable piece. But, call it determination or dumb stubbornness, I knew I just had to get the other part working.

I would’ve liked to refine the design (smooth out sliding motion, get the egg part working) and put more of a finish on this project (painting, coating), but I feel that I’ve put a lot of time and effort in my piece. It really turned out more complicated than I expected, with dozens of components in this tiny apparatus, each requiring multiple iterations and attempts of assembly. Let’s see, the cost should be around $10 materials + $10 machining + 48 hrs * $20/hr labor = $980. Huh. Add another $19 for exclusive edition and that makes a grand total of $999. Sounds like a deal to me.

Well although the project didn’t turn out as well as I had envisioned, I’ll just have to say that every step’s a learning experience. Lil’ peacock here won’t be becoming a family heirloom anytime, but aiming higher risks, not being afraid to make changes, even just learning a new tool– there’s the biggest takeaway.

May something beautiful come out of every door you unlock.