For the last assignment of the class, we had to use the CNC machine to create a 3D object out of wood from a 2D image. I went on thenounproject.com and found a bee design that I liked then began the process of using the Nomad CNC machine.

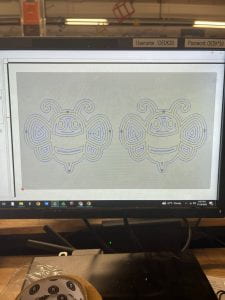

First I measured the size of the wood stock we were given to cut using a ruler and a caliper, then inputed it into Carbide Create. Next, I imported my svg file, resized it to fill up half of the stock, and duplicated it so I could cut both pieces out at the same time. I then had to create pockets for the interior shapes and a contour cut for the outline. Once I was finished I exported the file and opened Carbide Motion to start the next part of this assignment.

In this program, I went through the process of initializing the machine, using double sided tape to hold the stock down, and finding the origin of the stock. After all of this, I was ready to cut the wood. At first, everything seemed to be going smoothly until the wood piece started to move during the end of the pocket, so I had to stop the cut. I had to find another piece of wood, and after going through the process of remeasuring it, resizing my design, and probing the origin, I tried to cut again. This time, it made it all the way to around 85% done before the tape gave out again. At this point I was running out of time and only could find one last piece of usable wood. On my third attempt, the end mill broke during the first pocket cut and I was ready to quit. In the end, I decided to just use the other half of that wood to create one bee since I didn’t have time to cut more wood myself and restart the entire process. Once I triple checked that the piece was firmly taped down. I started the cut again with only one bee, and it took about 15 minutes to cut. Throughout this cut I had to pause and push down on the piece to keep it from moving multiple times, but I was finally able to complete a cut. However, due to the piece moving slightly during the cut, the bees’ antenna were broken off.

For post-processing, I began by sanding the edges down, then I used a spray paint to give the bee some color. Overall, I am satisfied with the results despite only being able to produce one machined piece. In the future, I’ll have to find a way to make sure the tape keeps the wood in place so that I don’t have to go through all of this trouble again. I also wasnt able to create as detailed a piece as I wanted to, and a lot of the pockets still had sawdust pieces in them that weren’t cut all the way off, possibly due to the size of the pieces I made.

Cost Analysis

Wood: One 1″x3″x8′ piece = ~$3

Double-sided tape: ~1/5 of a 10ft roll = $4

Spray Paint: ~1/4 of a can = $2

Labor: $15/hr for 6 hours = $90

Total = $99