The biggest lesson I got from this week was that the speed setting is really important when cutting. I had at least three completely failed cuts because I assumed that ramping up the power would mean that I could continue cutting at a faster speed. This proved to not be the case. The other important lesson was that the template items, especially those that rely on material flexibility, are not directly scalable–Shrinking the 1D hinge effectively makes it useless; to get it to work, I had to cut it down instead so that the gap and strip sizes remained the same. Similarly, the removable snap joint doesn’t work directly scaled up, the wood will snap before flexing enough. Finally, etching takes a long time.

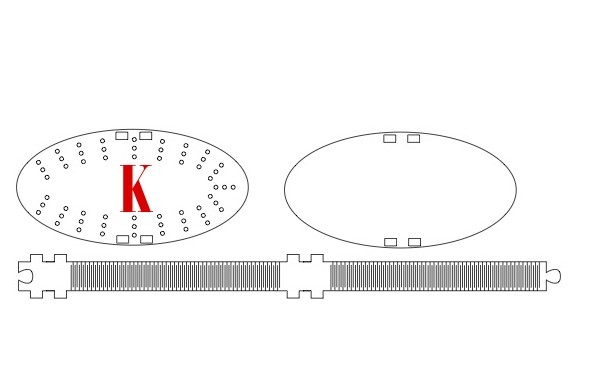

After three attempts this was my cribbage board model:

As soon as it came off the laser cutter, I pulled on the strip hinge and broke it in half which was disappointing. Interestingly, the small holes didn’t cut as perfect circles. Also, the finger joints don’t quite fit, I think because this wood is marginally thicker (~8mm) than that of the template (~5mm). Finally, it’s very difficult to figure out good border lengths with illustrator.

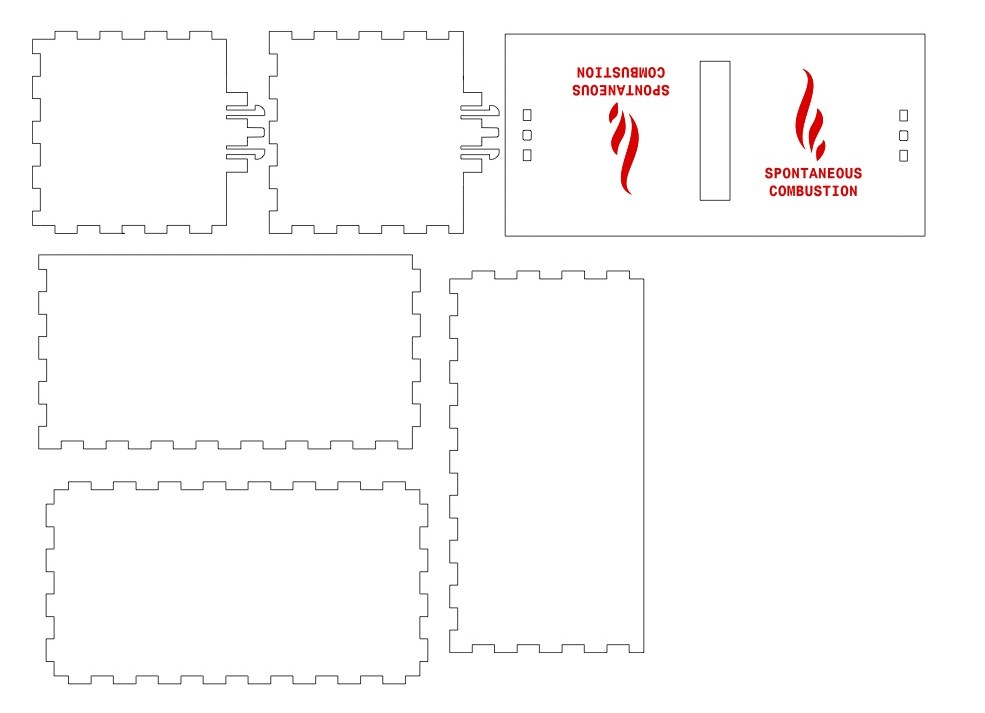

Here’s the box:

For my final attempt, I used the snap joints not scaled up at all from the template, this worked better than the last few but unfortunately I forgot to offset them so they stick up too high leaving a gap between the top of the box and its walls. Otherwise this cut went well.