For this homework, we were instructed to print an impossible object on the 3D printers found in the OEDK. This time I actually was convinced it was going to be an easy assignment because as a lab assistant and wet lab lead, I’ve spent so much time around the 3D printers. Again, I was proven wrong. Granted it wasn’t the most difficult assignment, but it definitely took more effort than I thought.

For this, I picked flexirex because I’ve seen it floating around the OEDK and I thought it looked super cool. It’s an impossible object because of its joints. They’re all connected without an opening so it definitely cannot be machined.

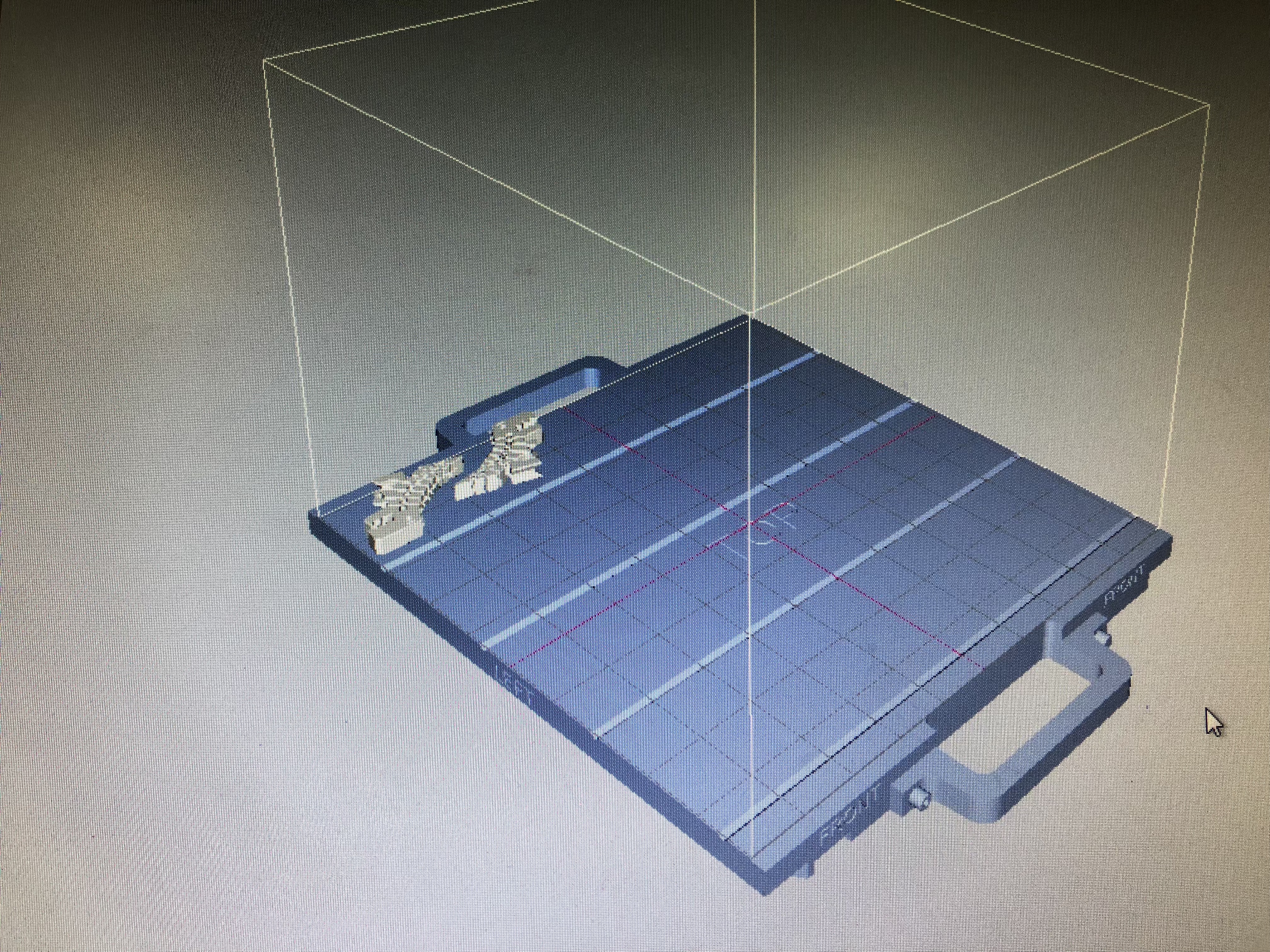

Many things went wrong while doing this assignment. As I was trying to recover the Sunday after beer bike, I thought this assignment was due the following Monday because that’s what canvas told me (thanks canvas reminders). So naturally, I panicked. I dragged myself out of bed and to the OEDK to quickly finish this assignment. When I got there, I realized all the 3D printers on the floor were being used so I panicked a little more, but then I remembered, the wet lab, duh. Luckily, the Objet was not being used because that printer is my first choice because it is without a doubt the best printer we have. I measured the inside of the gumball container and scaled up a little because my print, the flexi rex, was… flexi, so it can afford to be a little bigger than the actual container. Also, I was worried about the tolerances. So using my lab assistant privileges, I loaded my 2 flexi rexes into the printer and let it run. Surprisingly, it only took about an hour.

Some time between starting the print and finishing the print, I realized this assignment was not due the Monday after beer bike, so I was pretty relieved at that, but also, I was pretty relieved the tolerances were still okay after scaling the flexirex to about half its size. I was glad to be done, because we only needed two of the same object, right?

Nope. I realized on Tuesday, in class, the assignment had changed since last semester and we were actually supposed to use two of the 3D printers. Whelp. Probably should have read the instructions. That was going to be difficult because I know that the FDM printers don’t have as high of a resolution so it’ll be harder to print something this small. This was also around the same time where all other 3D printers decided to malfunction. The fortus was clogged (now unclogged, I think), the dimension died (hopefully not permanently), and the form2 was doing its own thing… again.

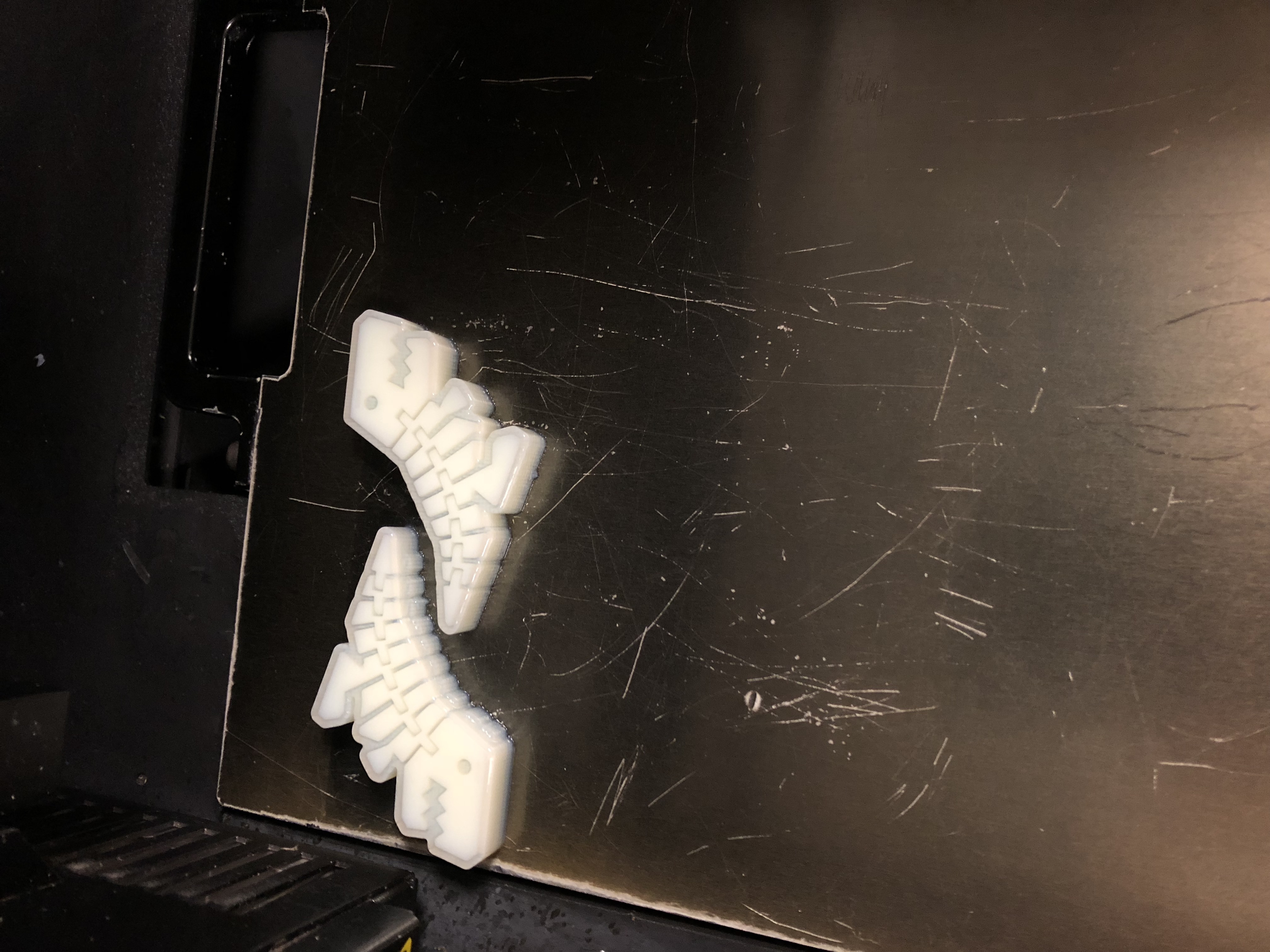

I tried printing the flexirex at the same scale on the M2 printers but I realized the tolerances were too low so the joints fused together. Then, I tried it on the form because it has a higher resolution and I was interested to see if it could do the joints, but again, it decided not to work. Finally, I went back to the M2s and just scaled up my print to 60 mm and hoped it’ll be big enough to print and small enough to stuff into the containers.

It actually worked! The tolerances were okay so the joints worked. They don’t work as well as the ones I printed on the objet, but they work pretty damn well for something that came off the M2 that’s scaled down to fit into a gumball container.

The moral of this story is never trust that the 3D printers will be working and READ THE INSTRUCTIONS. But seriously, if you need to print something on the 3D printers, give yourselves like a 2 day notice so you can print and reprint as needed… because you will probably need to.