For this assignment I created 2 metal diamonds using the water jet cutter. Certainly, I knew what a water jet was, but I never had the chance to use it. This was the first time I was able to use it.

The first step of this journey was to select the pictures that I wanted. I selected a cloud and a rocket. After selecting the pictures, I modified them by removing some small sections or adding lines because the water jet had some limitations.

Then I measured the thickness of the material, which was Aluminum in this case.

Once the vector file was ready, I created the cutting path in the ProtoMax software.

Then, I continued preparing the water jet by following the instructions provided in the wet lab. I used the piece of metal chained to the machine and I laid it on top of the Aluminum and under the nozzle. Then, I made sure that the water level was adequate (1/8 of water below the metal and that the drain is low enough). Also, I checked the sand level. One of the issues that I experienced with the drain of the water jet was that it was full of small plastic pieces, so I had to clean it.

Additionally, I selected the start position of the cutting path and started machining.

Once the parts were ready, I let them dry.

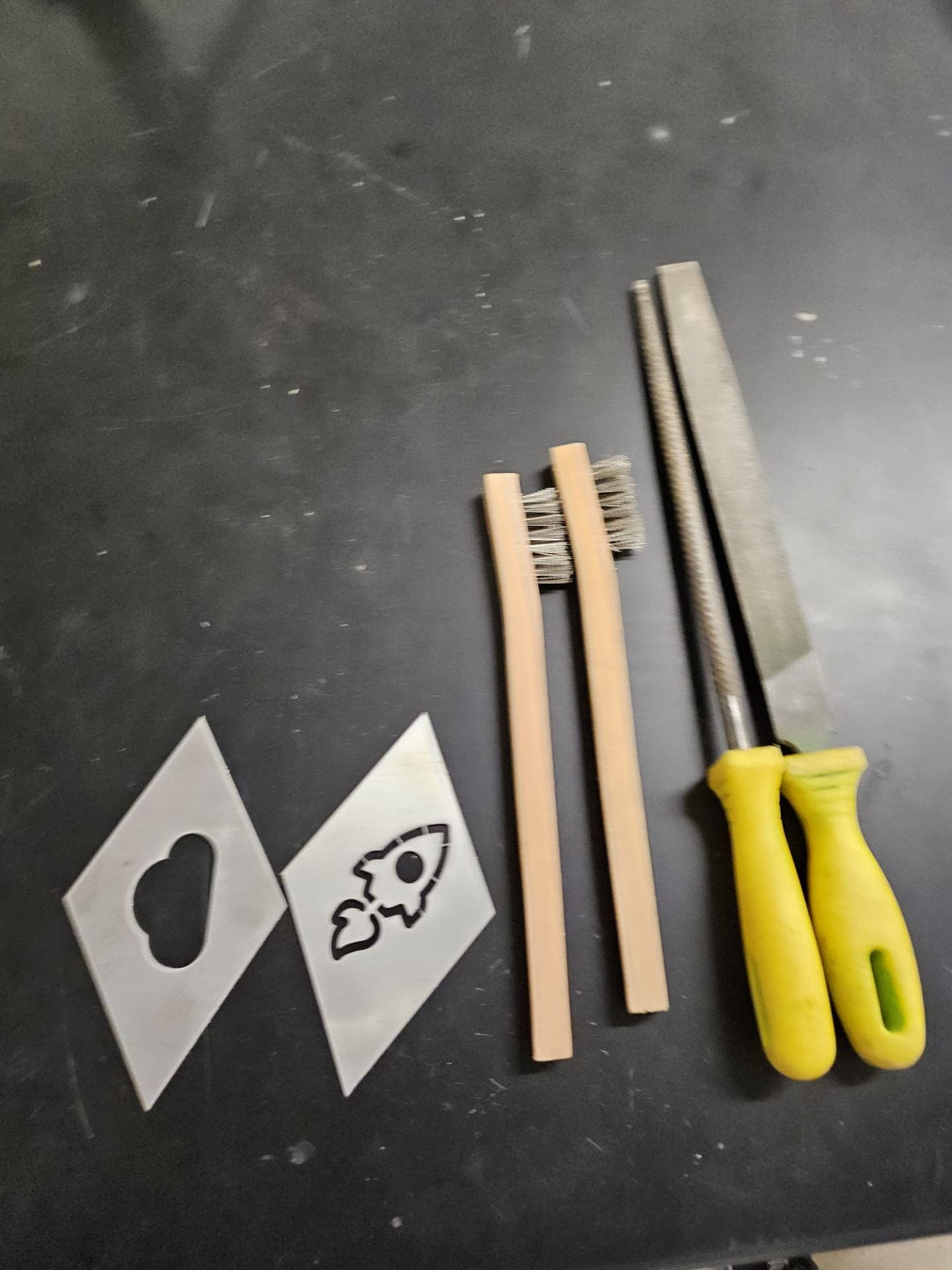

The next step that I did was use 2 different files and a metal brush to make the diamonds smoother. There were some small parts where I couldn’t use the files, so I tried using the metal brush.

Once I had smooth diamonds, I decided to use powder coating for painting them because I wanted to have the experience. It was the first time I heard about this type of painting. When I started painting painting everything was going well, but then I noticed that some parts were not being covered. I tried several things to increase the conductivity, for example, I cleaned the metal stand, moved the connected wire to another place, tried moving the diamonds to another place,etc. Eventually, I got the diamonds fully covered.

After painting, I moved the diamonds to the wet lab to put them inside the oven, but I think one of them lost painting in one of the edges while it was being positioned. Then, I set the oven to 400 degrees Fahrenheit for 20 minutes.

After taking the diamonds out of the oven, I noticed that they looked really different and they lost some painting, but they were shiny and pretty.

Finally, I calculated the Cost Model

Links for materials:

Metal

Aluminum Sheet 0.063 (Grade 5052)

Powder coat painting

https://www.eastwood.com/powder-specialty-color-sample-kit.html

File set

.https://www.amazon.com/Hardened-Strength-Warding-Triangular-Half-Round/dp/B07WDCBJ1G/ref=sr_1_3_sspa?crid=VOHGV5J9A0M0&keywords=metal%2Bfile%2Bcleaning%2Bbrush&qid=1697006092&s=hi&sprefix=metal%2Bbrush%2Bfor%2B%2Ctools%2C94&sr=1-3-spons&sp_csd=d2lkZ2V0TmFtZT1zcF9hdGY&smid=AL3I8LHZ8J0CO&th=1

Mini Stainless Steel Brush