I chose to add a geometric pattern inside of the diamond because I thought it would match the shape of the outer diamond. I started by making the file in Illustrator then plasma cut it. I ran into an issue with plasma cutting because for some reason my Illustrator file had a lot of duplicate shapes which caused issues with creating the g code. After fixing that issues and cutting it out I then used the angle grinder to remove all of the defects from the plasma cutting process.

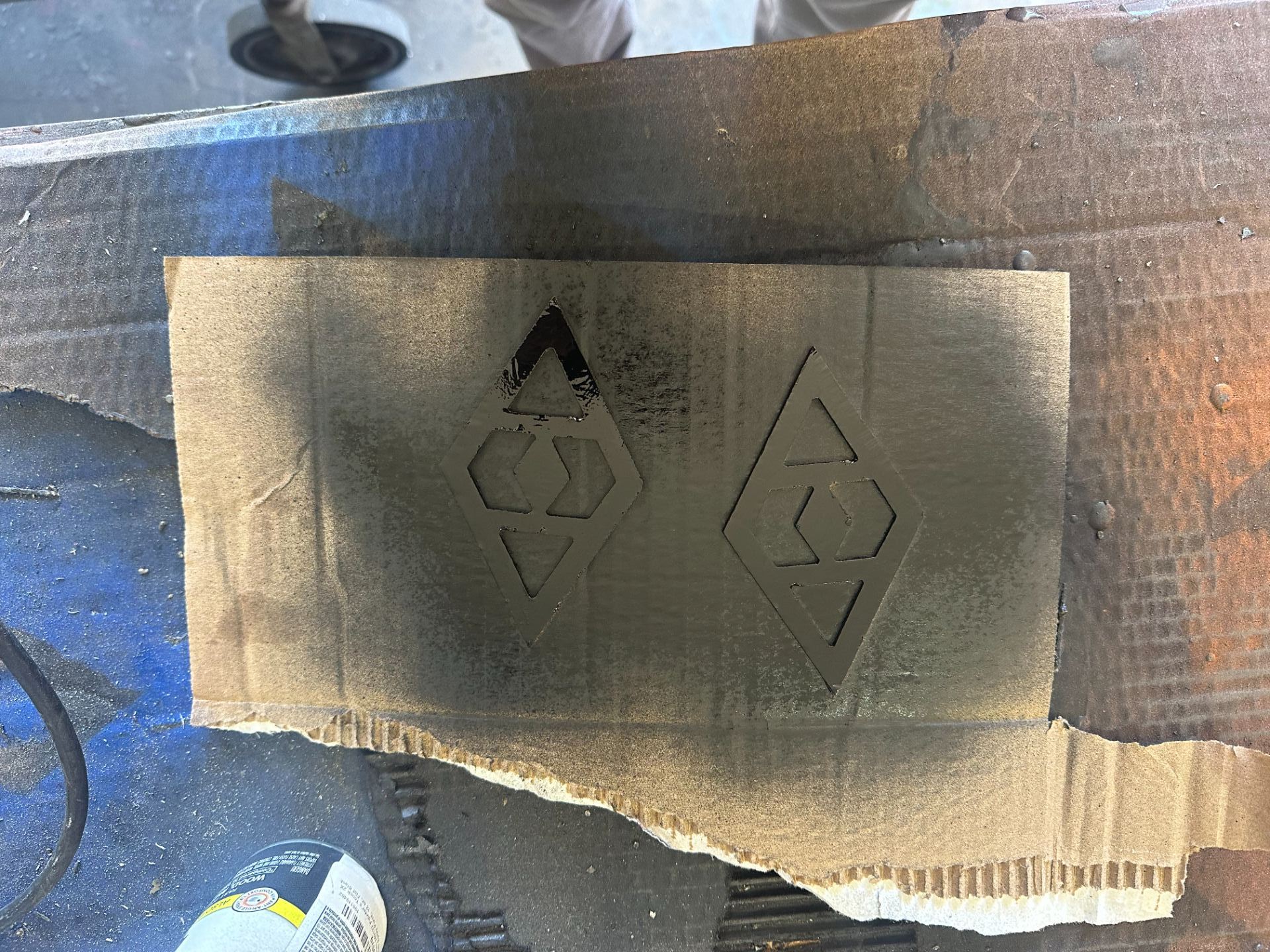

After angle grinding, I used the sandblaster to create a uniform surface finish. You can see the difference the sandblaster makes on the left part compared to the right. After sandblasting both pieces, I used black spray paint because I liked the look of it.

For each step I always had someone work in the same place after me so I could not get a photo of my clean workstation because someone was using it, I made sure to clean up all of my pieces, but let other people use the tools after me.

Cost analysis

I think the steel would cost roughly 5-8$ from what I found online.

I would charge 20 dollars an hour and even though I was at the OEDK for 5 hours, I was waiting to use tools for 2 hours and could do other things, so I will only charge for 3 hours which would be 60$.

I would estimate that it would cost 30 dollars an hour for machine time and I used the machines for 2 hours which would be another 60$.

that would be a total of 127$ for both pieces or 63.50$ dollars per piece.