The Marble Machine was comparatively easy (I think) to cad as there are no gears and no complex shapes to create. In class we have been learning the basics IronCad, and this project put our new found skills to practice. I found that IronCad was very different from other programs I had worked with and really took some getting used to. I was constantly putting things on shapes unintentionally, and the rotate function took me quite a while to figure out. By the final piece of the process though I think I got the basics of moving, resizing, rotating, duplicating, and rendering the final product.

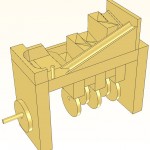

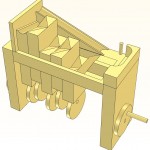

In cadding the machine I made each part in a similar order as they were physically made. I began by creating the basic what I will call frame of the machine- the two 5×3” side pieces and top part. These were just resized cubes and were simple to do. Next I made the pistos, minus the Vs that would be eventually made. The duplication feature would later prove very handy for that. Next I made the cylindrical parts, put holes in them and aligned them with the rod I would later remove from the final product as it is a fastener. The rods/cylinders/dowels that I left in the finished file were the small diameter (3/16”) dowel on top that was used as a bumper for the marble, and the little handle on the end that one turns the shaft with. Then I made the ramps by making a rib and then using a hollow half cylinder to create the groove running down the centers of each ramp. For the Vs, I used a hollow cube shape and then changed the cross section to make the angle of the V shallower. Then I rotated and resized the V so it was in its proper place. Once I had done one piston, I used the copy function to create 3 more and then simply resized the copies.

For the ‘turnaround’ I used a cube, sized it, and then used a hollow slot to make the curved part. I purposefully omitted the small popsicle stick pieces underneath because I feel if I hadn’t painted the machine they would have been unnecessarily. I think by painting and then re-sanding the paint off, I unintentionally changed the sizes of the pistons and they started to stick. The machine was working perfectly before it was painted aside from the marble occasionally rolling off the top part.