On this episode of Caz’s Adventures in ENGI 210, I tackle some mechanical drawings in Illustrator. I got to visit one of my favorite websites to waste time on, the 507 Mechanical Movements. This repository has hundreds (5.07 hundred precisely) of different mechanisms for translating different motions into other kinds. Highlights include rotary-to-linear, reciprocating motion, and intermittent motion. Our assignment includes recreating one of the pictured movements as a vector file. After looking through some of my favorites, optimizing for increased complexity and ability to draw in 2D, I came to two favorites: the tiny elevator and the most literal interpretation of horse-power.

I almost drew this in Illustrator, but its far too absurd |

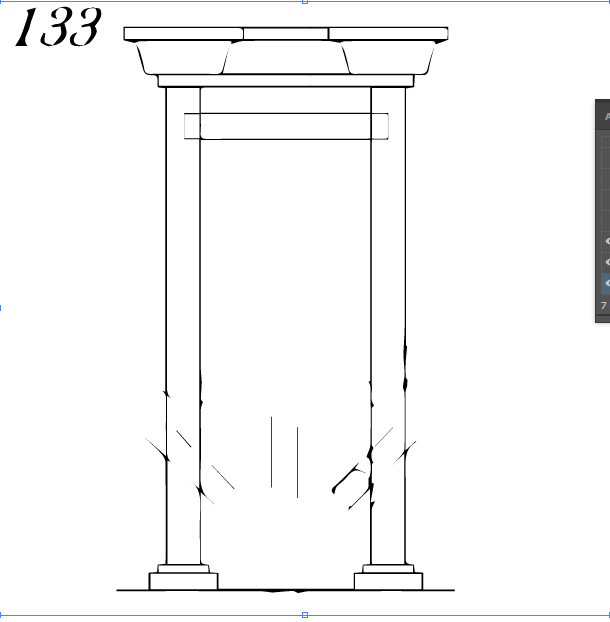

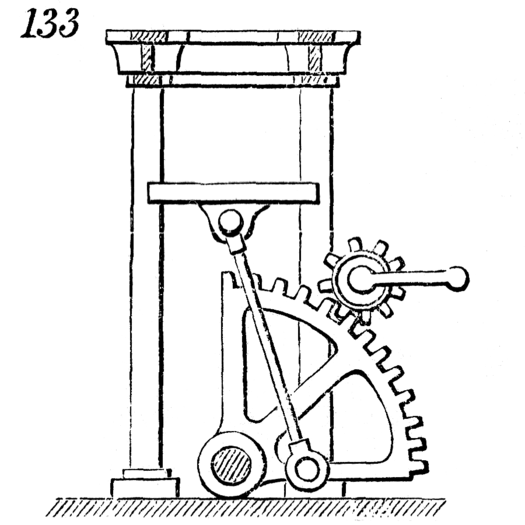

The mechanical movement I decided to go with |

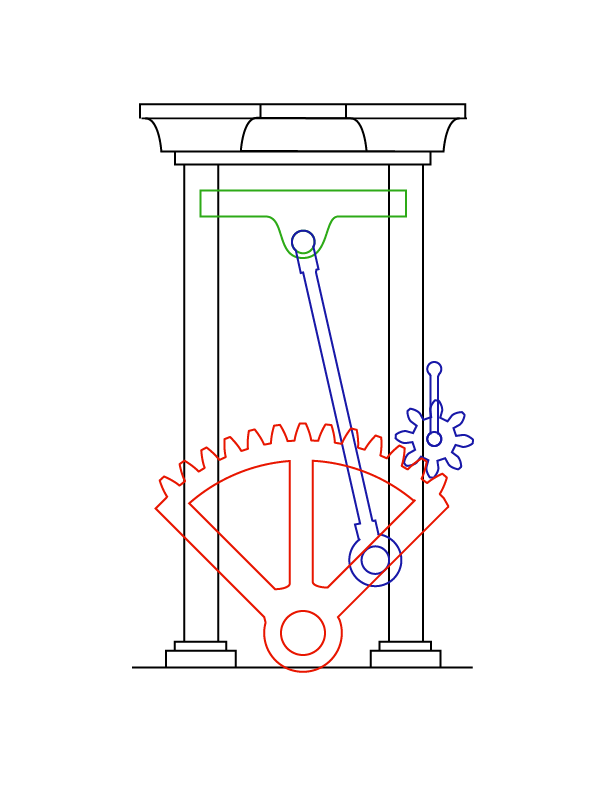

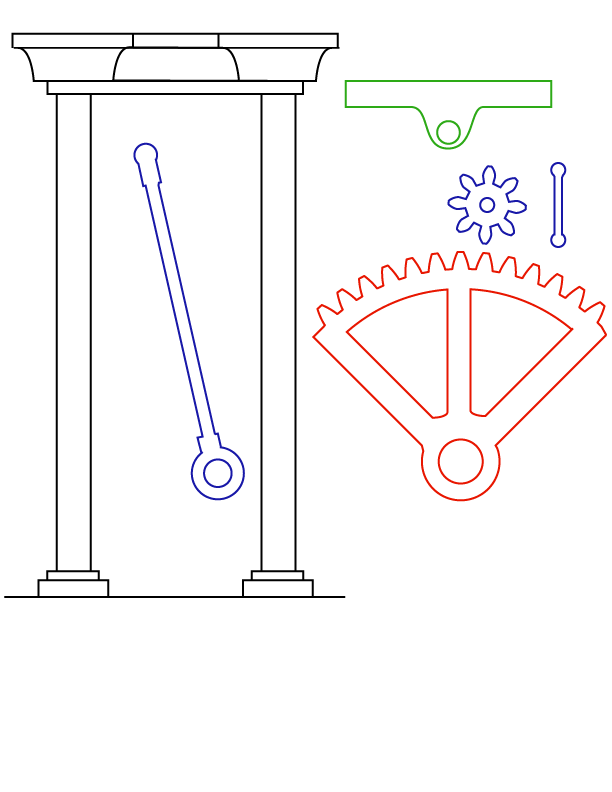

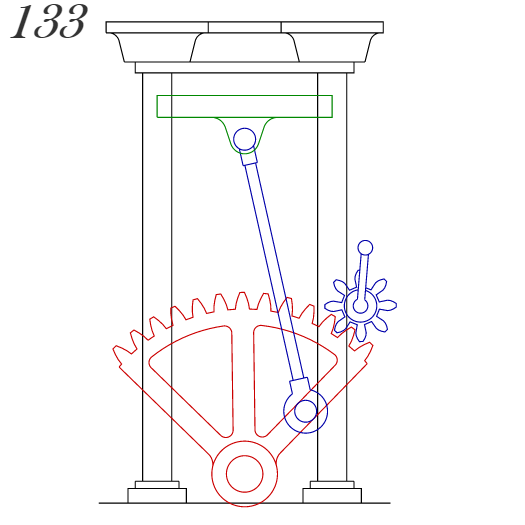

I settled on MM133 for several reasons, the largest being that it had more than one moving part. The small gear turns the big, which moves the linkage, which pushes the green floor up and down. I then pulled up the clean animated version in Illustrator, upsizing it to fit my canvas. Since it was a bitmap image, it became very blurry and pixelated, further proving the need for my new vector file. I listed out all the individual pieces and created a layer for each one to aid in organization. That way I could easily hide all other pieces while working on a single one.

First I attempted Live Trace as per the instructions. This was a complete failure, so I abandoned the idea almost immediately. Tracing the shapes would be easier and more fun. I started with the black backdrop, mostly using my four favorite bread-and-butter tools: select, line, cut, join. For the first time, I also used the pen tool to make some fancy curves. I also employed the shift key to lock directions to 45 degree increments more than ever before. The strong amount of non-orthogonal lines really got to me after a bit. Illustrator really is not optimized for this.

After creating the easy parts made of straight lines, I tackled the center red gear. I started by trying to straight trace every piece. This involved lots of making and cutting lines, trying and retrying, mirroring groups of pieces for symmetry, and other general tedium. I used the pen tool to trace a tooth of the gear and copied it, putting everything into place. At this point, I came to a startling revelation:

|

|

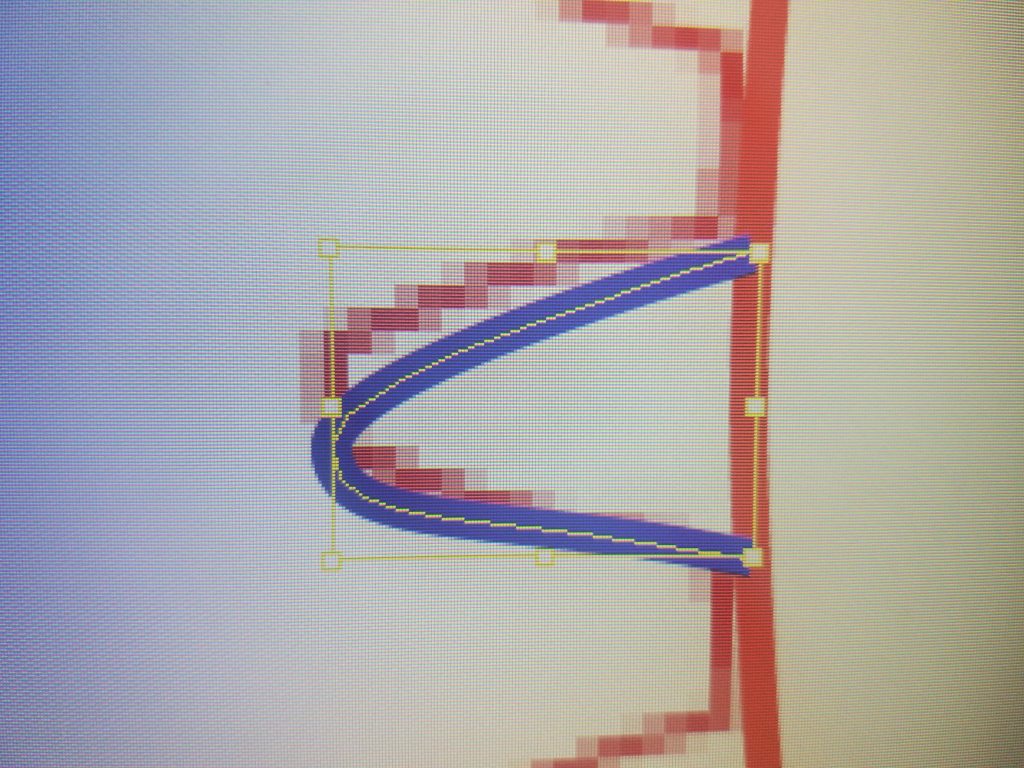

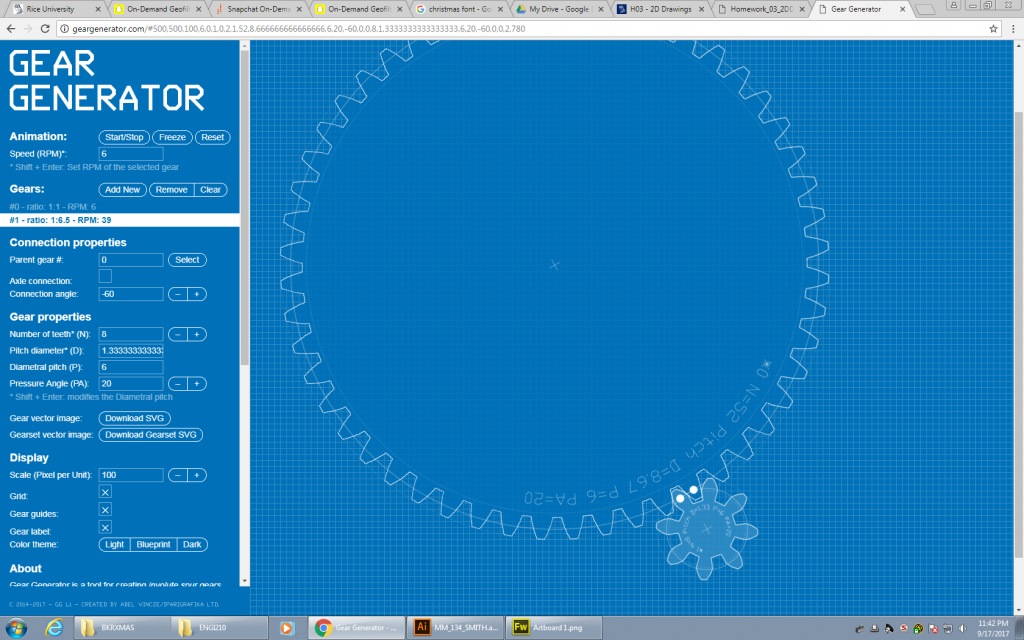

I am not just copying this image line for line. I should be modifying it and making it actually work as a mechanical structure. That is the ideal, at least. There was no way I could make everything about this model perfect: there’s not even an attempt to design the vertical rail for the elevator movement. Nevertheless, any hand-drawn gears would be absolutely abysmal, so I started over with another well-used website: gear generator

Here I made sure by gear teeth were a legitimate shape, not just some silly parabolas. Since the red 1/4 wheel had 13 teeth, I made a large 52 tooth gear and a small 8-tooth gear, then cut the large one into 4 pieces using my favorite tool, the scissors. I felt much better about these new real gears. I scaled the new 1/4 gear to my drawing, then calculated the proportion that I had shrank it and applied that scaling factor to the small gear. This way I could be sure they would mesh.

Overall, I am a little ambivalent about my results here. On one hand, the system I made is a very accurate representation of the 507 Movements design. On the other hand, there are still metaphorical holes from the original design that would make it hard to actually laser cut. If I wanted this as an actual design, I would need to redo a lot of the joints to make them more realistic, and I would need to design a better backplate than these purely aesthetic ionic pillars. As my final remark, I hope that I never have to use Illustrator again. Roughly 3 months ago, Jeremy told me that once I learned Solidworks, I would never want to use Illustrator again. That is 100% true. Solidworks would have made this significantly easier and better.