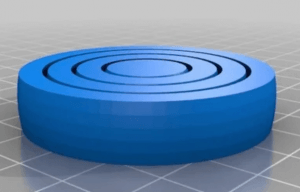

For this assignment, we were tasked with 3d printing an object that could only be reasonably made by a 3d printer. I found my design by searching “impossible” on Thingiverse.

There was a thin and a thick version, and I chose to print the thicker version. To start, I (unsuccessfully) predicted that the print should have a diameter of 35 mm, then scaled the object on a cad software. I started by printing it on the Fortus printer in the wetlab. We had problems with the machine calibrating, but then fixed it by changing the bed.

It printed with support on the bottom, so I had to submerge it in the lye bath for about a day.

Once it came out, It would not rotate and eventually broke after trying to force it. I realized that the gaps in the pegs between the rings were too small because of how much the design was scaled down.

I next decided to measure the gumball capsules with a caliper and realized that the piece could be 45 mm in diameter instead, so I tested this by printing a version scaled to that size on one of the makergears. This worked well and the piece could rotate with a small bit of force.

Knowing this would work, I printed the same thing on the fortus again, and after it came out of the lye bath (It was in there for more than a full day) it would rotate a little bit, but definitely less well than the makergear version.

Cost Analysis:

This project was a bit of a pain because of the failed print and long waiting times between prints and the lye bath. I probably spent a total of 2 hours working on this, not including waiting time. If I paid myself $18 an hour labor cost would be $36. The two fortus prints cost $16 combined, and I’d estimate the maker gear print to be around $3. That leaves these two prints to be a combined $55