Well well well. The midterm project has arrived. What shall we do? Well, initially we thought to make a working grandfather clock, but Dr Wettergreen quickly pointed out that this would be a very complex project that would be difficult to get working within the timeframe we had. So, we went to plan B – an orrery, also known as a solar system model.

The first thing we did was make some very low-fidelity prototypes to consider different ways of creating the orrery. There were various tradeoffs to consider, including – but by no means limited to – size, realism, ease of manufacture, and friction in the system. In the end, we chose to go with a model based off of concentric tubes, where each tube would rotate at a different rate, resulting in the planets orbiting the sun at different speeds, as we felt that it would be nice for our model to have roughly proportional orbital speeds.

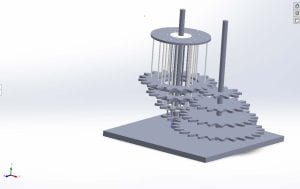

After we had this planned out, Harry made a CAD model of the system while I started cutting parts out of cardboard to test various aspects of the system, such as the gear spacing and the concentric gears.

After the tests and the CAD were done, we were ready to roll. It was just a matter of cutting and assembling all of the parts of the system. Most of the parts were made out of wood, of course, but there were also some acrylic disks made in lieu of bearings, since we needed different sizes of spacers, to the point that bearings weren’t very practical.

Harry laser cut all the gears, applied wax and clear coating, sanding, and assembled the main planet body, over the course of a few days. I cut out the planets and attached them to the dowels by drilling holes into the side of them. This was tricky since the dowel, and thus the drill bit used to make the hole, was quite nearly the size of the thickness of the planets. However, by taping the piece and clamping it tightly, we were able to prevent it from splitting when we worked on it.

Slides: https://docs.google.com/presentation/d/1nIuIkVTauNQ-K7RQ5Wkz1HPhi75mb-4ajCXC7TaY8yI/edit#slide=id.p

Video:

Cost:

Labor – $15/hr for 30 hrs = $450

Materials – $1.16 for plywood, $3.12 for acrylic

Machines – $450 ($150/hr for laser cutter, 3 hrs)

Tools – $50

Extras (Epoxy, sandpaper, etc) – $75

Total: $979.28