We began our project by analysing the problem description and beginning idea generation:

Problem and Constraints:

- Working Mechanical Model

- Uses one of the mechanisms given (eg gears, cams, pulley)

- Rotational vs Translational motion

- 2D processes only

- Stand Alone

- Parts move freely

- At least three moving parts

- Aesthetically appealing

- Must have a functional metal cut piece

- Crank or method to initiate motion

We had many initial ideas in our brainstorming session which utilised a variety of rotational and translational motions.

Initial Ideas:

- Trebuchet or Catapult

- Rotational motion

- Music Box

- Rotational motion

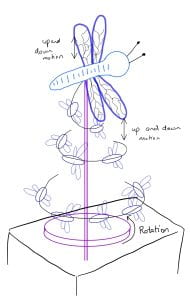

- Dragon Fly

- Moving Parts:

- Wings (up and down)

- Flower/mushroom (spin)

- Dragonfly (spin or up and down)

- Metal Piece: Wings

- Moving Parts:

- Fireflies

- Fly in Spirals

- Light up

- LED

- Glow in the dark paint

- Volcano Erupting

- Vertical translation lava eruption

- Moving roses sliding down?

- Using cams for up and down

- Ship in a storm

- Pitches left and right

- Waves move up and down

We selected our idea after discussing the design elements of each option, and concluded that the dragonfly proposal was the most feasible.

Selected Idea: Dragonfly spiral.

- One large dragonfly at the top.

- Wings move up and down [independently –> two mechanical motions]

- Whole spiral rotates

- Spiral of smaller dragonflies below. Suspended on wire

- We created an overall design sketch and individual sketches for the mechanisms before creating our first low-fidelity prototype:

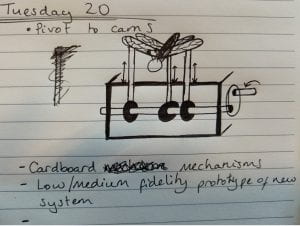

Idea Adjustment and Low Fidelity Prototype

However when we arrived in week 2 and tried to take this idea further, we realised that it would be very difficult to obtain both rotational motion and translational motion in the way that we desired, without using perpendicular gears. It would also have been difficult to get both motions to occur with the turn of a single handle, and we did not plan to create two separate turning mechanisms since we wanted the motions to occur simultaneously. Instead, we decided to pivot to a new mechanism that used cams to make the wings of the dragonfly flap up and down when the crank handle is turned.

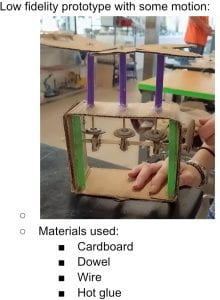

We created a sketch of this and built a low fidelity prototype which had some small motion but did not operate smoothly or exactly as desired.

We learned from this prototype that we would require something to weigh down the dowel pieces, otherwise they did not rest smoothly on the top of the cams. In this prototype we used washers but created a file to use with the water jet cutter in order to create our own weighted base pieces.

- Model is representative of the motion we aim to create. We will use three cams which are slid onto a dowel at different heights, in order to achieve a piston like motion where the body of the dragonfly moves exactly out of phase with the wings. The crank handle and dowel with cams rotates as it should. However the model imperfectly demonstrates the up-and-down motion of the wings and will need to be improved in subsequent protoypes.

- Notes to improve on for next prototype:

- Make circular cams, not ovals. Place them on the dowel offset, so that difference in height of motion is achieved

- Check the height of all parts before securing them in the frame.

- Make out of mdf for better quality moving parts especially

- Consideration of scale

Medium Fidelity Prototype

Our medium fidelity prototype enabled us to finalise the dimensions of our project, and helped us to troubleshoot where the issues in our motion were. The first problem that we would have to solve involved the dowels that supported the dragonfly has too great a range of motion back and forth. This meant that the base pieces would not stay in a stable position on the cams. As a result the dragonfly was flapping this way, that way, forwards and backwards (and over the Irish Sea 🙂 ). This had not been an issue on the previous model as we used straws to keep the dowels vertical as they moved up and down.

This model also dictated to use that we would need to make larger circles for the base of the dowels since the size of the cams meant the dowels got pushed further backwards and would fall off the cam. So we adjusted our AI file to ensure that the cams and base circles had the same diameter. This solved the problem.

Post-Processing and Assembly

For our final prototype, we used the same files as previously with the necessary adjustments made and then created our dragonfly AI file. We used the laser cutter to create our press fit box, cams, and dragonfly. We opted to stain our main frame with a dark mahogany stain to give the appearance of a dark wood. The main issue that we encountered with this was in staining the dragonfly etching. When the stain was applied to these sections, it was very hard to then remove all of the excess with a cloth so there are uneven staining areas around the laser etching.We used a wood wax on our dowels so they remained light in colour. This provided contrast in our wooden design aspects.

We used silver and blue spray paints to decorate the dragonfly wings, and a black spray paint with blue vinyl sticker to finish the dragonfly body.

We used the water jet cutter to create weighted base pieces for the dowels so that they would hold the dowels down, enabling them to rest smoothly on top of the cams. I used a file to smooth the slightly uneven centre hole cuts and then used the sand blaster to finish the three identical pieces.

We used wood glue for our final assembly except for the joining of the metal to wood where we used cyanoacrylate.

Final Product

Our final product motions as we had planned it to. The one thing we didn’t consider was that the wings might also rotate if not fixed to the body. This makes it seem like the dragonfly flies a little off kilter.

Cost Breakdown

- Materials:

- 13cm x 5cm x 3.5 mm Aluminium: $4.05

- Birch Plywood mdf sheet from OEDK shop: $15

- Wood glue: $3.47

- Walmart

- Paints and stains: Free with OEDK use

- Equipment:

- Free with OEDK access: $0

- Labour:

- 2 people @ 15 hours each

- $15 per hour based on Alice’s current on campus wage

- Total: $450

- Project Total: $472.52

Slide Deck: https://tinyurl.com/AliceCassidySlides

Video of motion: