To begin with, I chose a rocket svg from thenounproject. I then used Carbide Create to make a file that the CNC machine could cut. I made pockets and contours for each of the lines at either a depth of 0.07in, 0.1in or the bottom of the stock depending on which line it was. I added tabs in three places to ensure that the piece wouldn’t move as it was nearing the end of the cut.

Figure 1: SVG of my rocket

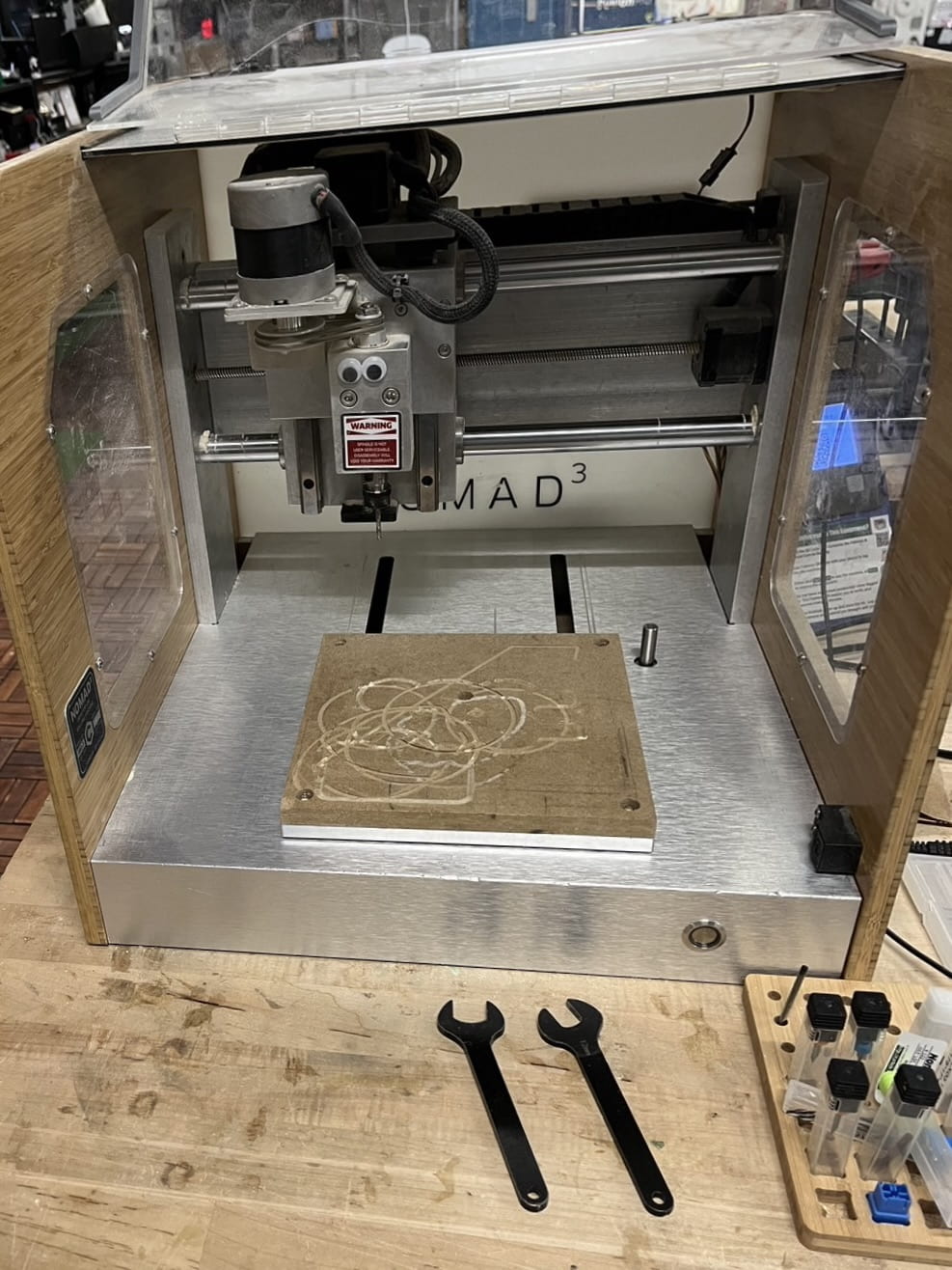

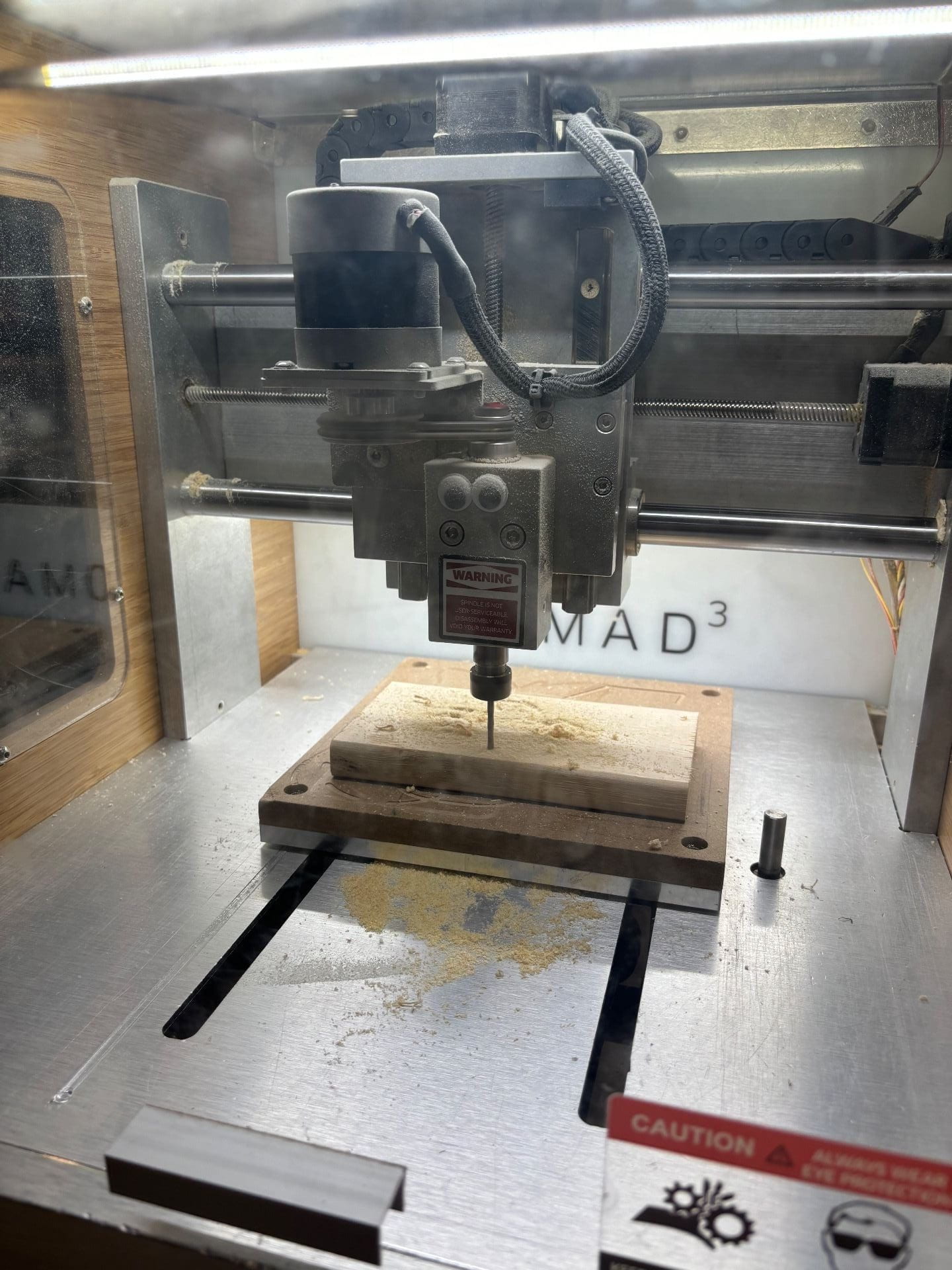

I used double-sided tape to stick the wood down and then began the setup and cutting process. Each cut took around 16 minutes.

Figure 2: CNCing the piece

I had a couple of issues with the process. The first time, as seen earlier, the file was at an angle so when I cut it, it was 3x3in but when I removed it from the wood it was around 2x4in so did not meet the requirements of the homework. I rearranged the file and cut it again and the second attempt was good. For the third attempt, the wood came unstuck so I had to recut it and then the fourth attempt was good!

After cutting each of them, I pressed them out of the surrounding wood.

Figure 3: Pieces before sanding

I then sanded them with 120 grit and then 400 grit sandpaper. I then applied a butcher block conditioner to finish it.

Figure 4: Final product

Cost of Production

1×4 wood from Home Depot is $3.88 for 8ft. I used around 1ft. $0.49

Butcher Block Condition from Amazon is $8.86 for 12oz. I used around 0.5oz. $0.37

Labor at $15/hr for 6 hours. $90

Overheads at 15% of total cost is $13.63. This covers OEDK costs such as lab assistants, the wear and tear of the CNC machine and extra materials like tape.

Total Cost: $104.49

Clean Workspace: