For the last weeks of class, we were tasked with using the CNC to cut a noun out of the wood. For the project, I used the Carbide 3D Nomad 3 and it was relatively easy once I was able to start the project. My biggest issue starting the project was the probing and initializing of the machine because I was having trouble setting it up. The biggest issue was getting the probe to stay in place and not move on my piece of wood and the probing bit’s disappearance, so I had to use a square end mill. Once I was able to work through those challenges the project was pretty straightforward. I used Carbide Create to create all the toolpaths from SVG files and simulated it, so I would have an idea of how I wanted it to look.

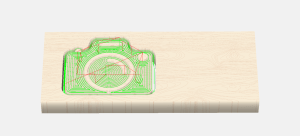

Figure 1: Carbide Create Simulation

In Carbide Create I had to make sure the stock size of the wood matched the actual wood I used to prevent errors and make sure it cut all the way through. To make this cut I used two pocket cuts to get the two different depths and then a contour cut to cut all the way through.

Once I placed the wood in the Carbide 3D Nomad 3 I put double-sided tape down to make sure the wood wouldn’t fly away and injure myself and/or destroy the machine. I uploaded all the toolpaths into a c2d file into Carbide Motion and probed and initialized the machine to make sure the left-hand corner was zeroed. Finally, I started the cut and each cut took about 30 minutes to be completed from start to finish in the machine.

Figure 2: Camera Cut

Cost:

3 hours in total to figure out how to change the bit, cut, and set up the machine. For my work, I rate it at $15/hour. The materials were given to me for free by the OEDK. This project cost in total of $45.