In the final project, we were asked to make a pair of chess(black&white) using the method of casting and molding. The main idea is to use the CNC to cut the positive shape and use oomoo to make the negative mold, and eventually use the mold to create the positive chess.

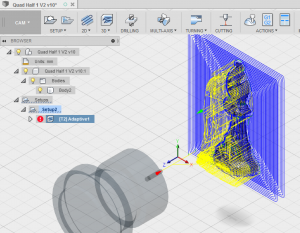

One of the biggest part in this project is to prepare the file using fusion 360. We need a BRep body so as to use the CAM mode. So we need to convert the chess from mesh to T-splines and then to BRep. As mentioned in the tutorial video, the number of triangle in the mesh body is too high to convert, I used the autodesk remake to decrease to number to half of the original. However, it still failed when trying to convert to T-splines. Later I realized that the default for remake is to convert to triangular mesh, not the quad mesh we want. After changing the conversion setting, I am able to make the body into BRep and open the CAM mode.

One of the biggest part in this project is to prepare the file using fusion 360. We need a BRep body so as to use the CAM mode. So we need to convert the chess from mesh to T-splines and then to BRep. As mentioned in the tutorial video, the number of triangle in the mesh body is too high to convert, I used the autodesk remake to decrease to number to half of the original. However, it still failed when trying to convert to T-splines. Later I realized that the default for remake is to convert to triangular mesh, not the quad mesh we want. After changing the conversion setting, I am able to make the body into BRep and open the CAM mode.

Under the CAM mode, I could set up the right coordinate system and adjust the box into the size of the wood we were going to cut. Then I put the right data for the 3D adaptive clearing and simulate the whole process. After making sure that everything is right, I exported the G-code of it .

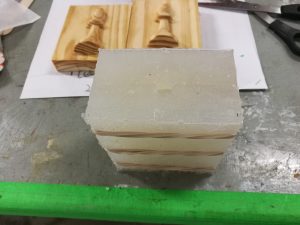

When we were trying to load the G-code in the flashcut, there was a problem that the G-code of fusion 360 can not be recognized in flashcut. Thus, we used easal to convert the code into the G-code that flashcut support. And use the G-code editor in flashcut to delete ‘M9’ code, which cannot be read. This time, the file worked and we sand them after the cut to make them smoother. The product looks pretty good.

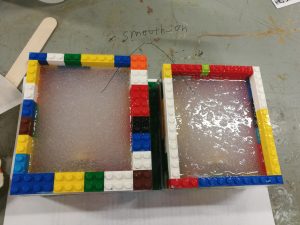

For the mold, we use the LEGO to build a box and put the wood block in the middle. Then we pour the smooth-on into the box and left them there for 24 hours to cure. And it is pretty easy to take off without mold release.

Since we didn’t make the key for the molds, it was painful to line the two parts and we also found out later that the two molds were slightly different. We used the rubber band to tight them together and made a funnel so that we can pour the liquid plastic better. Then we post process the chess with dremel and sand paper.

For the black one, because we didn’t know that we have black ink for liquid plastic, we spray paint a lot in a cup to get the liquid paint and add it into the liquid plastic. This is really interesting that this actually increase the time to cure and the product become more elastic. After finding the ink, we also made a regular black chess.

For the black one, because we didn’t know that we have black ink for liquid plastic, we spray paint a lot in a cup to get the liquid paint and add it into the liquid plastic. This is really interesting that this actually increase the time to cure and the product become more elastic. After finding the ink, we also made a regular black chess.

The final products look like this: