When looking through 507 Movements, I was interested with numbers 96 & 205. My original idea was to take the cam design in 96 and add it to a big cam shape to push out the rods. As the middle dowel is spun, the cam in the middle spins. Depending on where the cam is at, the rod will be pushed out different distances.

My first prototype was all cardboard, so I could see how the pieces fit together and moved. From this I discovered I could make the fan shape and stand piece one instead of two separate pieces. I also realized that I needed an end piece on the side without the handle to keep everything together. The shape of the cam was very drastic, so I decided to look at changing it after I worked on the medium fidelity.

I made my medium fidelity out of all wood, which is what the majority of my final prototype is made out of. Before cutting out all the pieces, I checked the different fits with the dowels. The fit for pieces that don’t move was good. For the moving pieces, the fit was too tight and I could not get the dowel on, so I increased it 0.01 in and it worked. The hole in the moving rod was too big, so I decreased it 0.01 and it worked. I then went to cutting out all the pieces and seeing how they worked together.

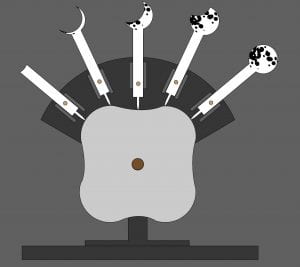

I added a spacer between the handle and stand piece. I already had the spacer between the stand piece and cam.

The rod is connected with the dowel and between the holders. It will rest on the cam as seen when the cam is spinning.

This is the front view of the medium fidelity piece. The handle is in front. The middle part is the stand piece. The back is the cam. I taped the rod holders on the inside.

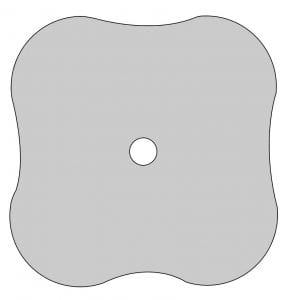

After I found the correct sizing for these pieces, I started working on my cam’s shape. I needed it to move the rods noticeably, but also not become stuck. I tried a few iterations of the cam until I came to the final shape shown below.

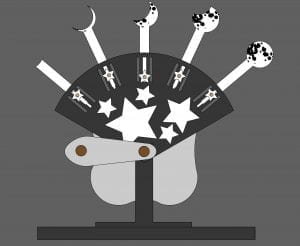

I then started working on the final design. I was interrupted during this stage by the coronavirus pandemic. Not all of the pieces were finished and put together yet. I used most of the same pieces from the medium fidelity, but processed. I decided to make a nighttime design for the overall piece. I stained the two sides black and laser etched stars out of them. I stained some wood white and would have laser cut and etched the rods out of it in the shape of different cycles of the moon. I water jet the cam out of aluminum, but did not process it. I stained the main dowel and spacers black. The rod support still needed stained. The base also needed to be laser cut and stained.

General idea of my final design. Brown circles are where the black stained dowels go. Dark grey rectangles on the sides of the rods are where the rod support pieces go.

To start the movement a person grabs the handle dowel and moves it in a circular motion. This cause the handle to move causing the middle dowel to spin. When the middle dowel spins, the cam inside spins. As the cam inside is spinning, the rods are being pushed up and then falling down.

External position. 45 degree turn. The cam has turned 45 degrees and the rods have moved to different height. The stars that hold the rod dowels have also moved position based on the rod height.

Internal view of 45 degree turn. The cam has turned 45 degrees, while the rods are at different heights. The ends of the rods are still touching the cam.

While I was unable to finish this project, I am pleased with the work I have done so far. I am planning on finishing it next semester once the school opens back up. Throughout the prototypes I was able to determine what needed to be fixed or new pieces to add that I had not previously thought of. This project definitely took a lot of trial and error to make sure everything fit and moved the way I wanted.

The overall cost for materials would be around $51.36

Wood: $10 for 2 pieces from OEDK

Aluminum: $12.45

Stain: $15.96

Paintbrushes: $8.97

Glue(maybe needed): $3.98